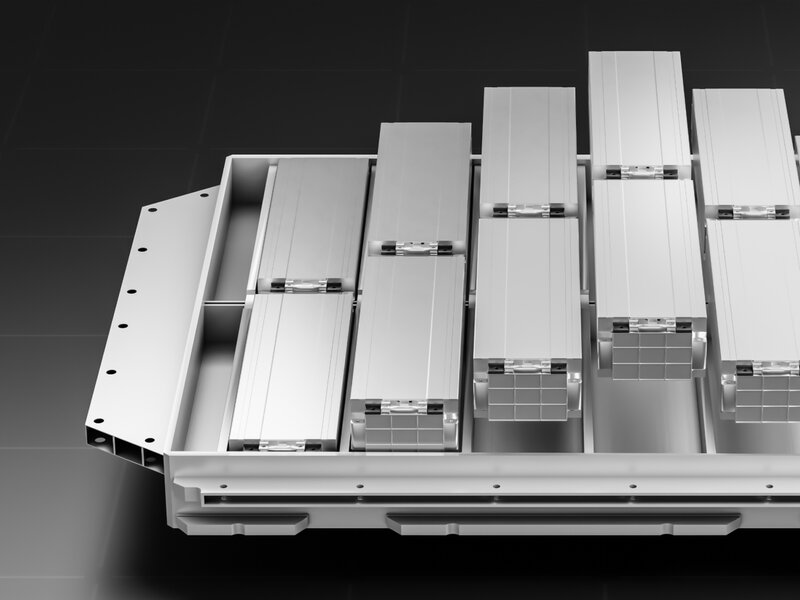

In the automotive sector and, in particular, electric mobility, productivity and operational efficiency are key to meeting market challenges. Tecno Logica designs numerically controlled multi-axis and multi-spindle milling systems, integrated with robotic systems, to guarantee greater performance in terms of operational continuity and intelligent production management in smaller spaces.

- Optimised performance: multi-axis and multi-spindle machining to reduce cycle times and optimise the use of production space.

- Process integration: fully automated management from handling to machining, reducing manual intervention.

- Scalable solutions: systems that can be configured by capacity and type of machining, adapting to different production requirements.

We design custom systems tailored to every need.

Optimizing the production process is not just a goal—it’s a competitive advantage. Our systems ensure a fast return on investment by boosting productivity and lowering operating costs, providing an effective response to the challenges of an ever-evolving market.

In a dynamic and constantly evolving sector such as electric mobility, Tecno Logica creates integrated and high-performance solutions for the factory of the future. The multi-axis and multi-spindle numerically controlled rotary transfers for milling guarantee high productivity while minimizing the space occupied and the costs related to logistics and material flow. The workpieces held by fixing templates (hydraulic or pneumatic) that can be equipped automatically are presented to the various processing stations (4, 6 up to a maximum of 8 stations) of the machine without the need for tooling or balancing in the sequence of processes, effectively eliminating positioning errors and guaranteeing the flexibility of the system. The integration of milling centers with robotic handling solutions minimizes the resources used to run the plant. The main operations on the individual aluminum profiles and/or battery supports managed by the system are the following:

- Automation and handling

- Cutting

- Probing

- Milling

- Drilling

- Laser marking

- Deburring

- Chip removal

- Palletization

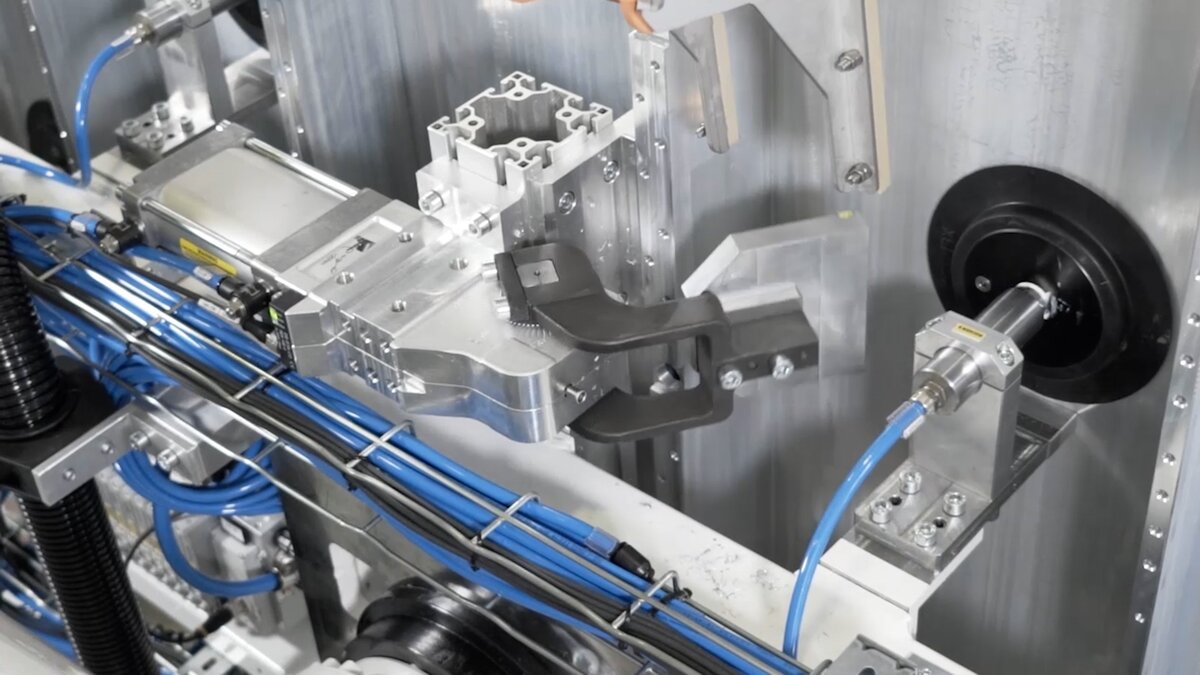

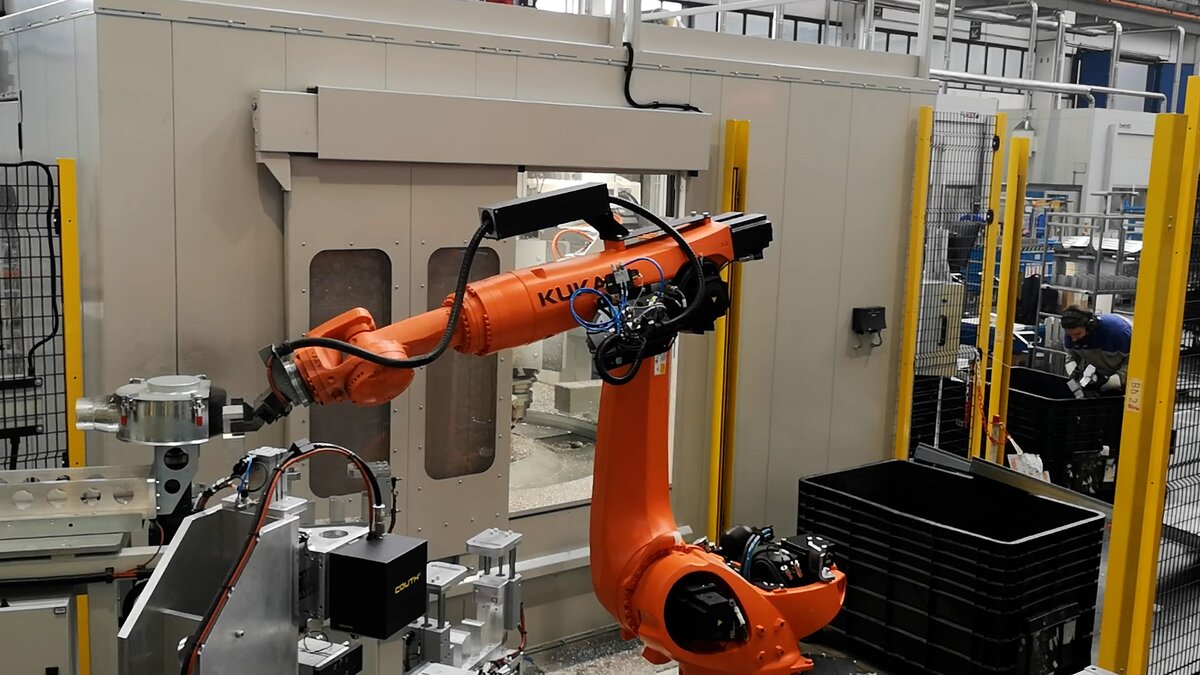

Automation & Handling

Automation and management of product flows through the use of advanced technologies to improve production efficiency, precision in handling and reducing the need for human intervention.

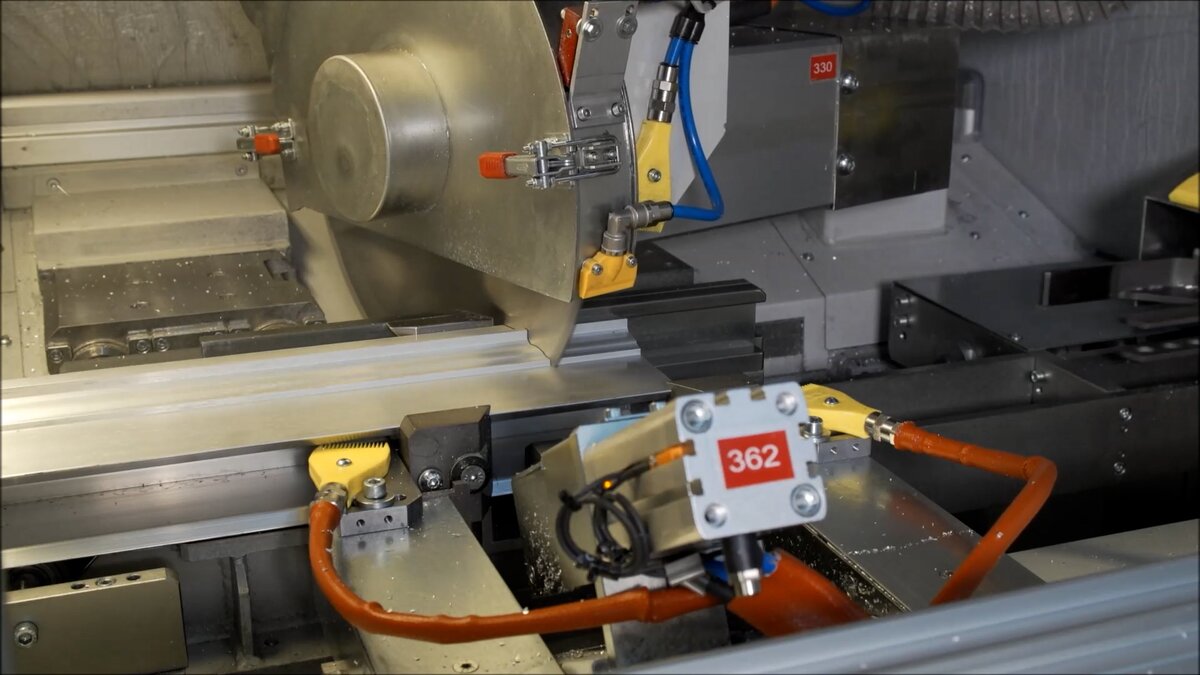

Cutting

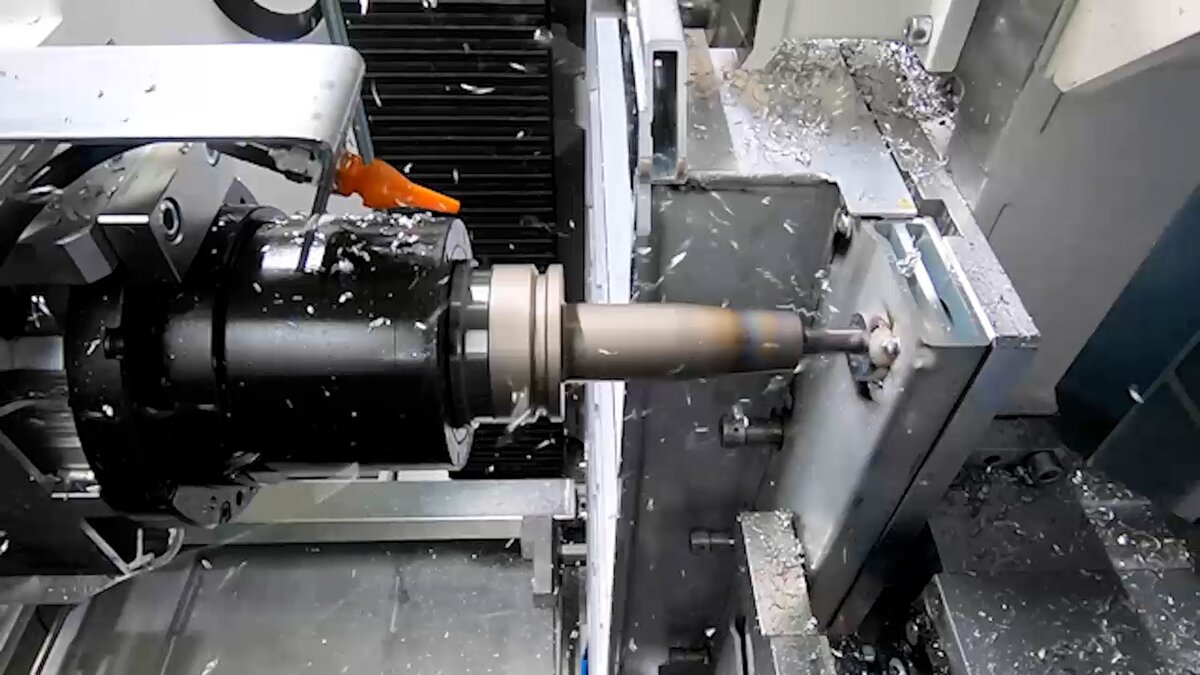

CNC cutting systems for aluminum bars capable of performing complex cuts on different profiles with high precision and repeatability.

Probing

Part inspection and probing solutions automate part setup, in-cycle calibration, tool setting, and broken tool detection. Combined with automatic offset update systems, our technology reduces setup time and improves process control, so you can machine your parts with greater confidence.

Milling

Part inspection and probing solutions automate part setup, in-cycle calibration, tool setting, and broken tool detection. Combined with automatic offset update systems, our technology reduces setup time and improves process control, so you can machine your parts with greater confidence and peace of mind.

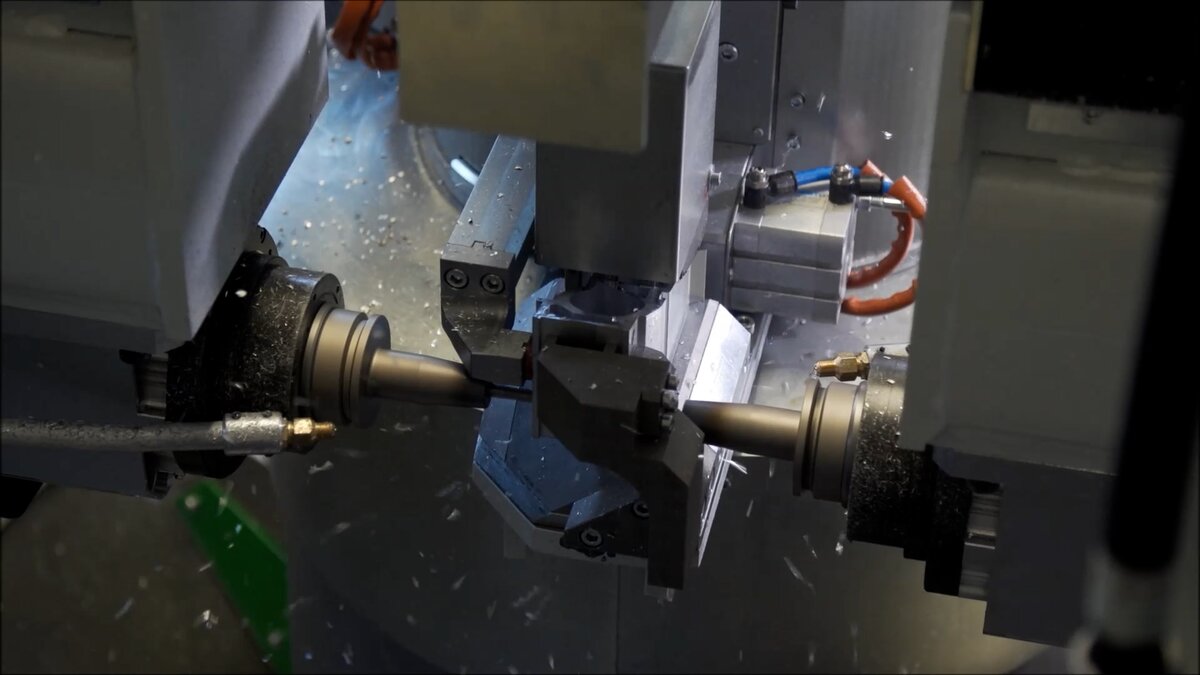

Drilling

High precision and repeatability drilling with automatic systems configurable for different applications. Cycle time reduction is achievable thanks to the possibility of distributing chip removal operations on multiple stations within the same machine

Laser Marking

Versatile and multipurpose laser markers for fast and clear marking of a wide range of materials. We integrate laser marking systems complete with internal vision system, full-field autofocus and marking analysis tools.

Deburring

Mechanical deburring systems for the rapid and uniform removal of burrs from components. Automatic removal of protrusions resulting from machining, stamping or die-casting operations.

Chips removal

Automatic chip removal to maintain production efficiency and continuity through chip conveyors for handling large production volumes continuously.

Palettizing

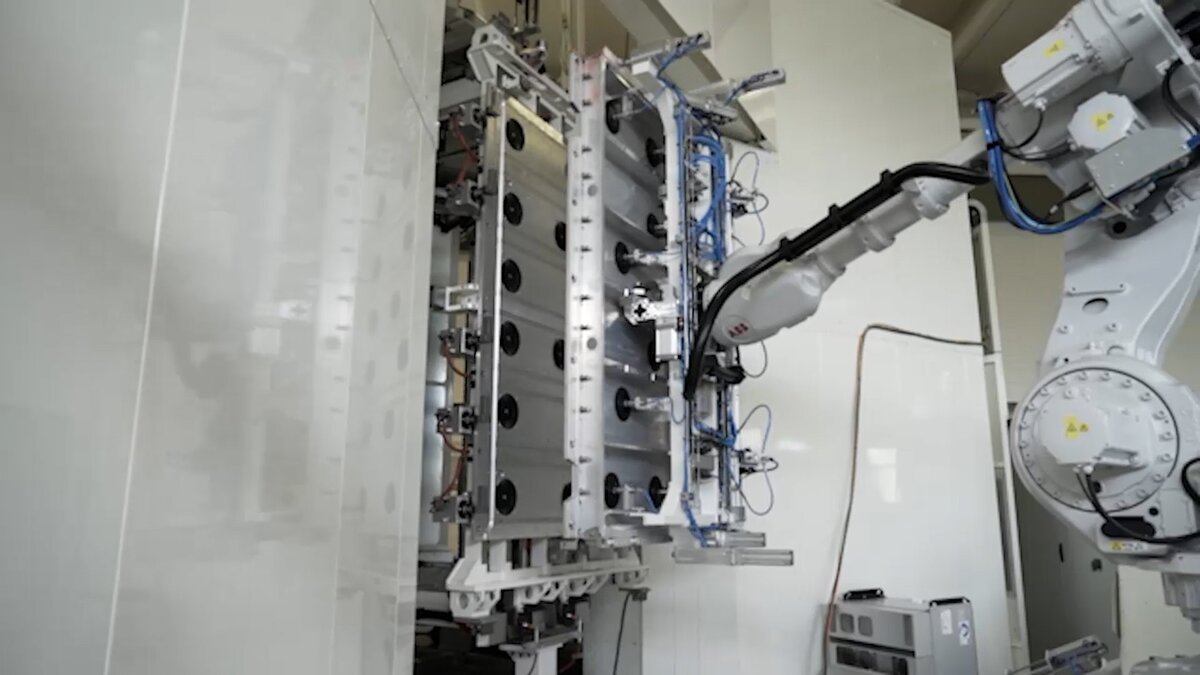

Palletizing robots/manipulators are programmed to pick up and place products on pallets precisely and quickly. These robots can handle a wide range of automotive components, from small parts to large and heavy components.

Discover Tecno Logica’s solutions

In a dynamic and constantly evolving sector such as electric mobility, Tecno Logica creates integrated and high-performance solutions for the factory of the future. The multi-axis and multi-spindle numerically controlled rotary transfers for milling guarantee high productivity while minimizing the space occupied and the costs related to logistics and material flow. The workpieces held by fixing templates (hydraulic or pneumatic) that can be equipped automatically are presented to the various processing stations (4, 6 up to a maximum of 8 stations) of the machine without the need for tooling or balancing in the sequence of processes, effectively eliminating positioning errors and guaranteeing the flexibility of the system. The integration of milling centers with robotic handling solutions minimizes the resources used to run the plant. The main operations on the individual aluminum profiles and/or battery supports managed by the system are the following:

- Automation and handling

- Cutting

- Probing

- Milling

- Drilling

- Laser marking

- Deburring

- Chip removal

- Palletization

Automation & Handling

Automation and management of product flows through the use of advanced technologies to improve production efficiency, precision in handling and reducing the need for human intervention.

Cutting

CNC cutting systems for aluminum bars capable of performing complex cuts on different profiles with high precision and repeatability.

Probing

Part inspection and probing solutions automate part setup, in-cycle calibration, tool setting, and broken tool detection. Combined with automatic offset update systems, our technology reduces setup time and improves process control, so you can machine your parts with greater confidence.

Milling

High precision milling with automatic systems configurable for different applications. We guarantee speed, repeatability and process quality, integrating high performance micro-lubrication solutions.

Drilling

High precision and repeatability drilling with automatic systems configurable for different applications. Cycle time reduction is achievable thanks to the possibility of distributing chip removal operations on multiple stations within the same machine

Laser Marking

Versatile and multipurpose laser markers for fast and clear marking of a wide range of materials. We integrate laser marking systems complete with internal vision system, full-field autofocus and marking analysis tools.

Deburring

Mechanical deburring systems for the rapid and uniform removal of burrs from components. Automatic removal of protrusions resulting from machining, stamping or die-casting operations.

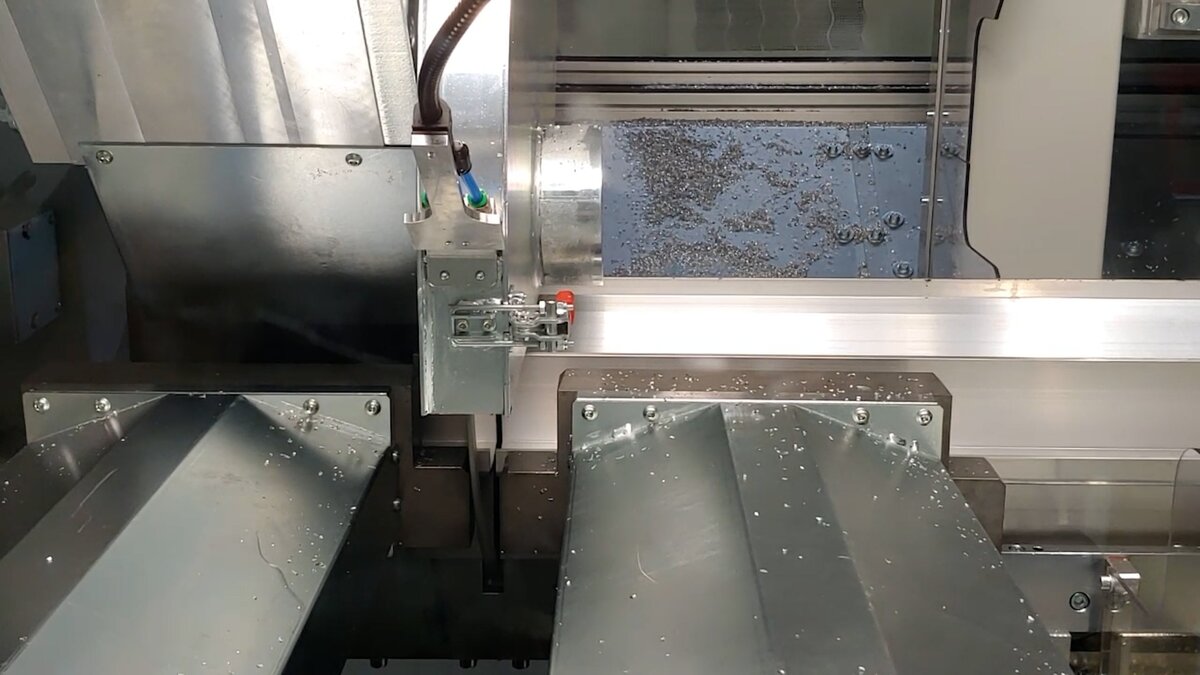

Chips removal

Automatic chip removal to maintain production efficiency and continuity through chip conveyors for handling large production volumes continuously.

Palettizing

Palletizing robots/manipulators are programmed to pick up and place products on pallets precisely and quickly. These robots can handle a wide range of automotive components, from small parts to large and heavy components.

Discover more applications for the Automotive sector

We are ready to listen, analyze and build tailor-made solutions for you.

Fill out the form below and one of our experts will contact you as soon as possible.