Tecno Logica creates automated and semi-automatic systems for the production of radiators, designed to guarantee operational continuity and optimization of processing times, with the possibility of managing different production configurations. The modular approach allows to adapt to the capacity and variability needs of the models, always maintaining high quality standards.

- Integrated and optimized process: complete automation from cutting to welding and final testing.

- Constant quality: consolidated technologies to guarantee precise and reliable joints, with automated tests to verify performance.

- Production modularity: versatile systems able to adapt to different configurations and operating capacities.

We design custom systems tailored to every need.

Thanks to the modularity and flexibility of our solutions, we optimize every stage of the production process—enhancing performance, reducing cycle times, and ensuring a quick return on investment. Regardless of the sector, our goal is to deliver systems that transform industrial manufacturing, increase competitiveness, and meet technological challenges with innovative, high-performance solutions.

Systems designed to efficiently assemble radiators using both automatic and semi-automatic processes. Includes the following main functions:

Tube Cutting

- Automatic Tube Cutting Machines: These machines cut tubes precisely to the required lengths using advanced cutting technologies. The process is fully automated, ensuring high accuracy and consistency.

- Semi-Automatic Tube Cutting Stations: Operators assist in feeding tubes into cutting machines, which then perform the cutting operation. This allows flexibility in handling different tube sizes and materials.

Welding

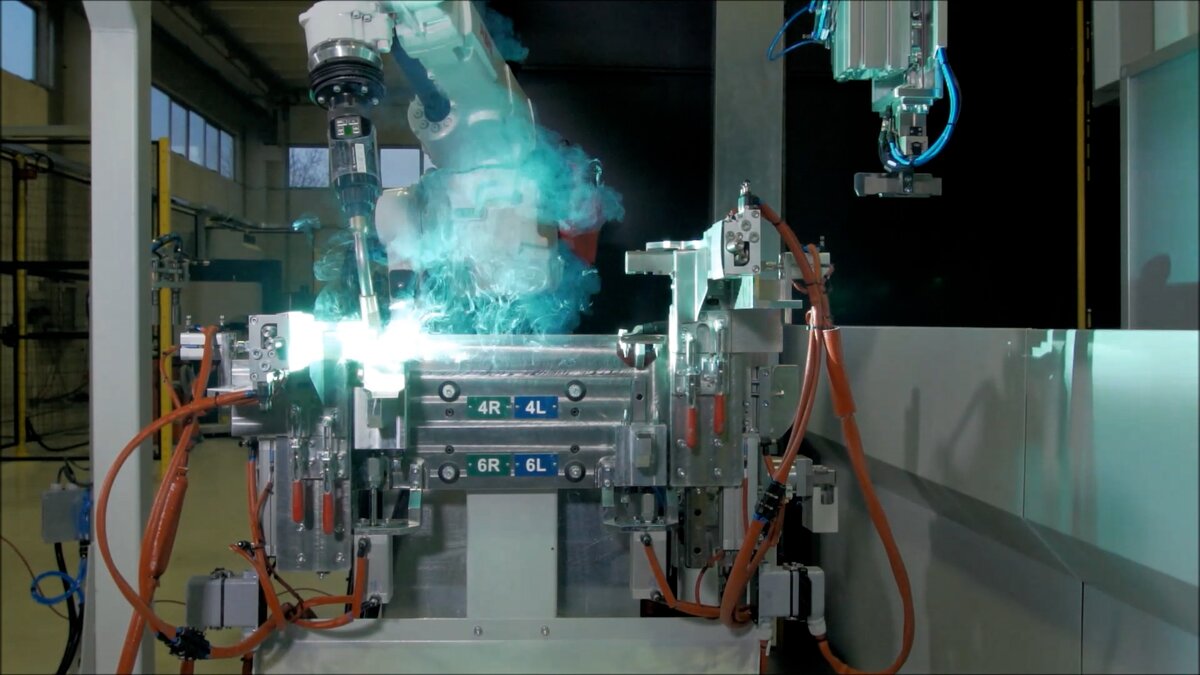

- Automatic Welding Robots: These robots perform high-precision welding of tubes and other components. They are programmed to follow specific welding patterns, ensuring strong and reliable joints.

- Semi-Automatic Welding Stations: Skilled operators handle welding torches and perform welding manually, with the assistance of jigs and fixtures to ensure accuracy.

Final acceptance tests

- Automated Test Systems: These systems perform various tests on the assembled radiators, such as pressure tests, leak tests and performance tests. The results are recorded and analyzed to ensure that each radiator meets quality standards.

- Manual Test Stations: Operators perform additional tests and inspections, using specialized tools and equipment to verify the quality and functionality of the radiators.

Tube Cutting

CNC cutting systems for aluminum bars capable of performing complex cuts on different profiles with high precision and repeatability.

Welding

Robotic cells to perform welding and assembly efficiently. These cells can be configured to perform different operations, such as welding frames and other structural parts through MIG/MAG, spot or laser welding.

Testing

Palletizing robots/manipulators are programmed to pick up and place products onto pallets precisely and quickly. These robots can handle a wide range of components, from small parts to larger and heavier components.

Systems designed to efficiently assemble radiators using both automatic and semi-automatic processes. Includes the following main functions:

Tube Cutting

- Automatic Tube Cutting Machines: These machines cut tubes precisely to the required lengths using advanced cutting technologies. The process is fully automated, ensuring high accuracy and consistency.

- Semi-Automatic Tube Cutting Stations: Operators assist in feeding tubes into cutting machines, which then perform the cutting operation. This allows flexibility in handling different tube sizes and materials.

Welding

- Automatic Welding Robots: These robots perform high-precision welding of tubes and other components. They are programmed to follow specific welding patterns, ensuring strong and reliable joints.

- Semi-Automatic Welding Stations: Skilled operators handle welding torches and perform welding manually, with the assistance of jigs and fixtures to ensure accuracy.

Final acceptance tests

- Automated Test Systems: These systems perform various tests on the assembled radiators, such as pressure tests, leak tests and performance tests. The results are recorded and analyzed to ensure that each radiator meets quality standards.

- Manual Test Stations: Operators perform additional tests and inspections, using specialized tools and equipment to verify the quality and functionality of the radiators.

Tube Cutting

CNC cutting systems for aluminum bars capable of performing complex cuts on different profiles with high precision and repeatability.

Welding

Robotic cells to perform welding and assembly efficiently. These cells can be configured to perform different operations, such as welding frames and other structural parts through MIG/MAG, spot or laser welding.

Testing

Palletizing robots/manipulators are programmed to pick up and place products onto pallets precisely and quickly. These robots can handle a wide range of components, from small parts to larger and heavier components.

Discover Tecno Logica’s solutions

We are ready to listen, analyze and build tailor-made solutions for you.

Fill out the form below and one of our experts will contact you as soon as possible.