The hollow-core panel represents a versatile and lightweight solution for the furniture and door sector, with production requirements that vary depending on the intended use and finishes required. Tecno Logica offers complete plants for the production of hollow-core panel, with engineered technologies in both large-scale productions and configurations geared to maximum flexibility. and fully integrated high mix and productivity.

- Complete process: integrated and automatic management of every stage, from material preparation to finished product.

- High production performance: maximum operational continuity and proven technologies to ensure rapid return on investment.

- Operational versatility: plants that can be configured by capacity and product type, adapting to every production need.

We design custom systems tailored to every need.

Whether it’s high-performance batch production or highly flexible systems for batch size one, our solutions integrate advanced technologies for drilling, milling, hardware insertion, assembly, and automated handling—ensuring a streamlined production flow and minimizing waste.

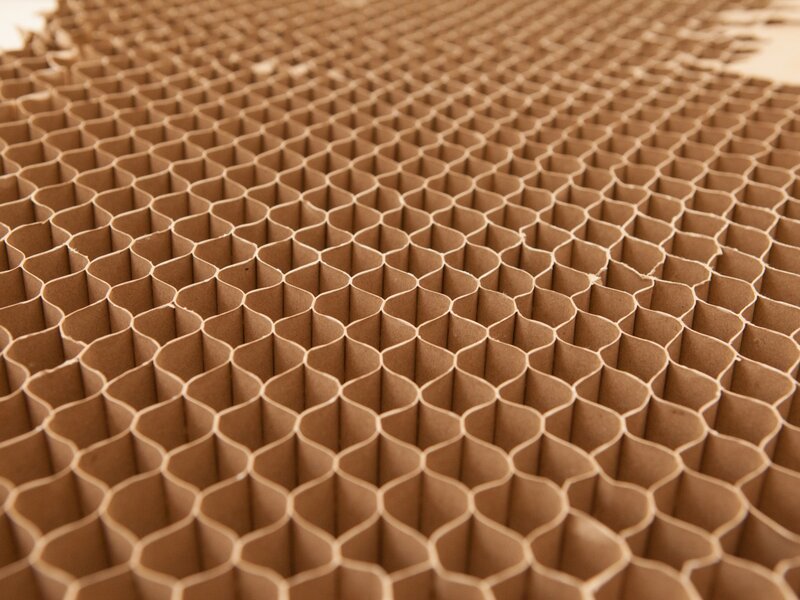

Tecno Logica offers integrated solutions for the automated production of honeycomb panels, a key technology for the RTA furniture sector, door production and all other areas where the combination of lightness and strength is required. Our plants are designed to meet the demands of high-volume production, but also to ensure maximum flexibility within the production mix, depending on the customer's needs.

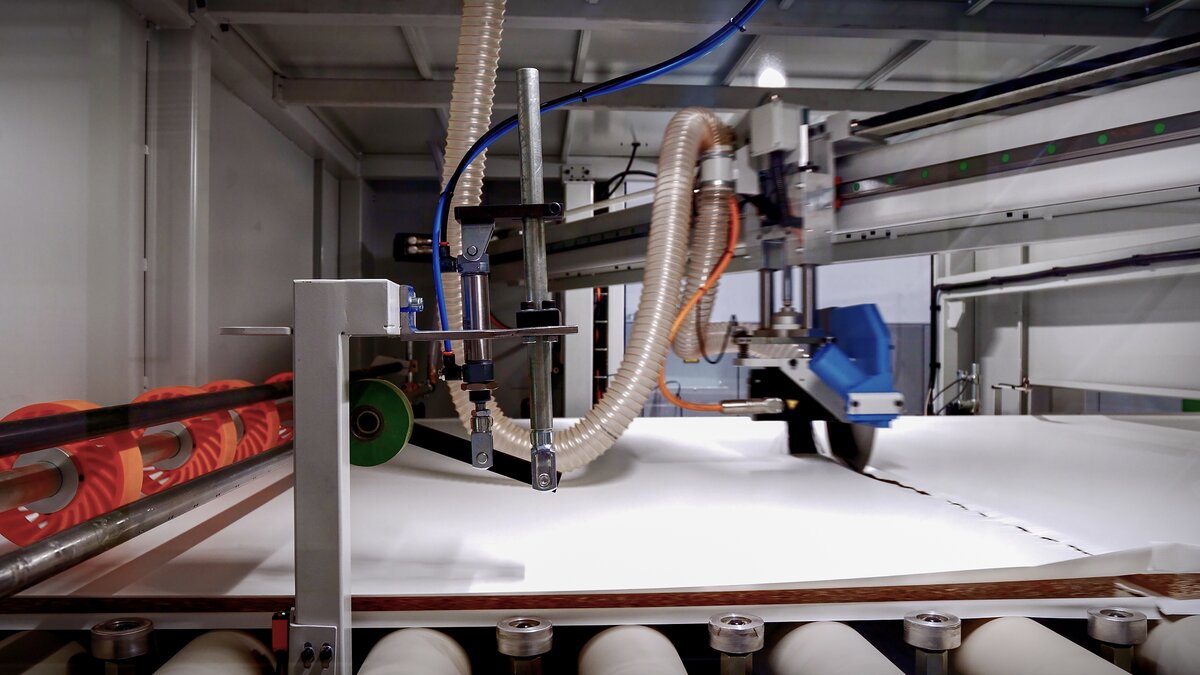

The honeycomb panel's production includes several crucial stages, such as the cutting and preparation of the materials, the assembly of the internal structure (if any), the insertion of the honeycomb and the subsequent closing of the panels with a surface finish. With our facilities, we manage each step of the process in an automated manner, optimising the efficiency and quality of the final product.

In addition, we offer a complete handling system that integrates all necessary operations, from material picking to the management of machine loading and unloading, ensuring a continuous and uninterrupted flow. Our solutions are perfect for those who need to handle large volumes, but also for those who need to respond to flexible production demands, with small production batches and a quick setup for product changeovers.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Stile cutting

Precise cutting of materials for the construction of the honeycomb panel, ensuring waste optimization and maximum production efficiency. The process ensures high quality and uniformity of the components.

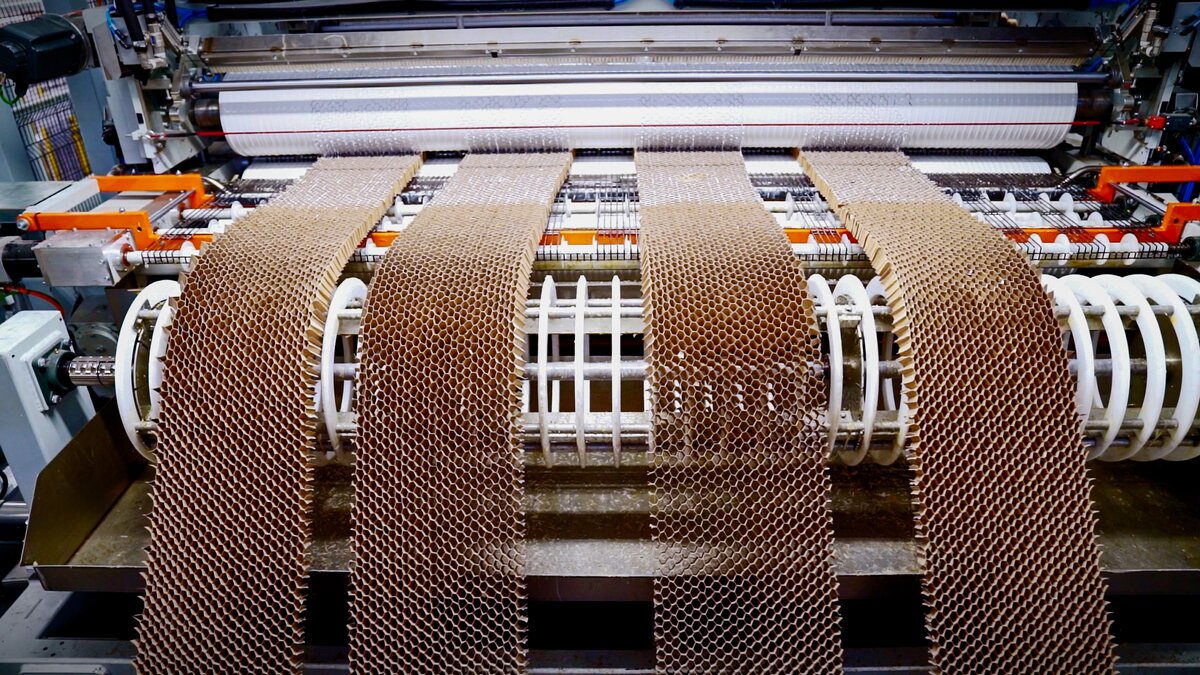

Honeycomb expansion and handling

Expansion, gluing and handling of the honeycomb for the construction of light panels. The process guarantees a uniform opening of the honeycomb structure and precise positioning, ensuring stability and lightness to the finished panel.

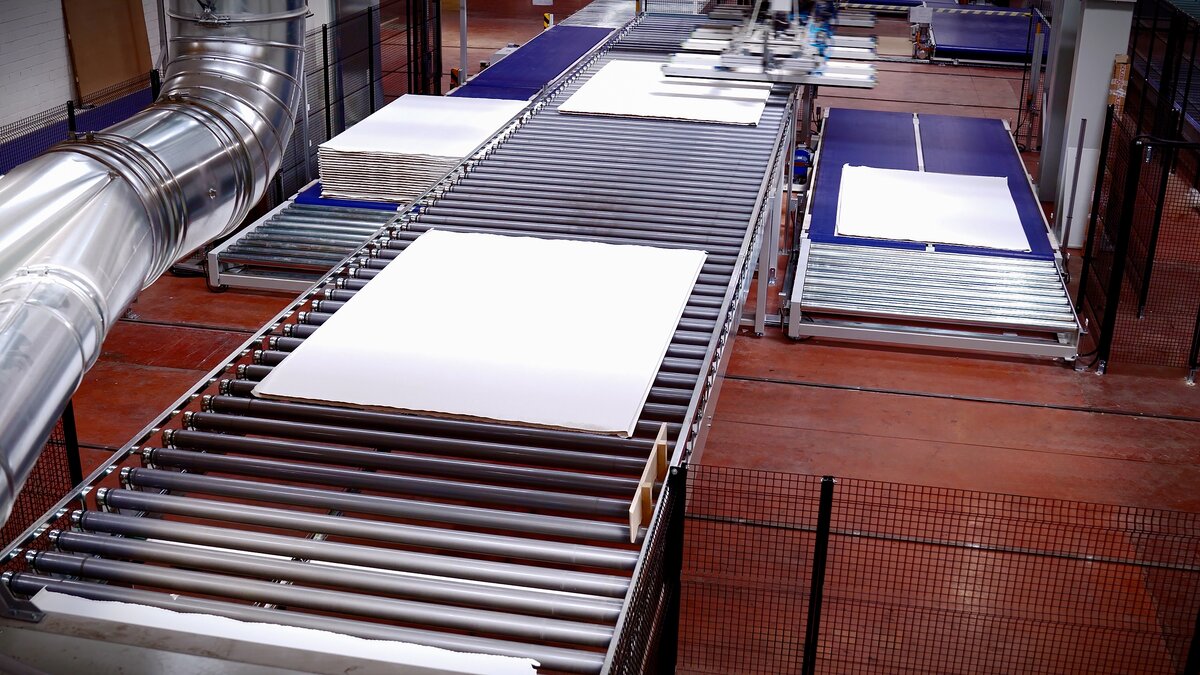

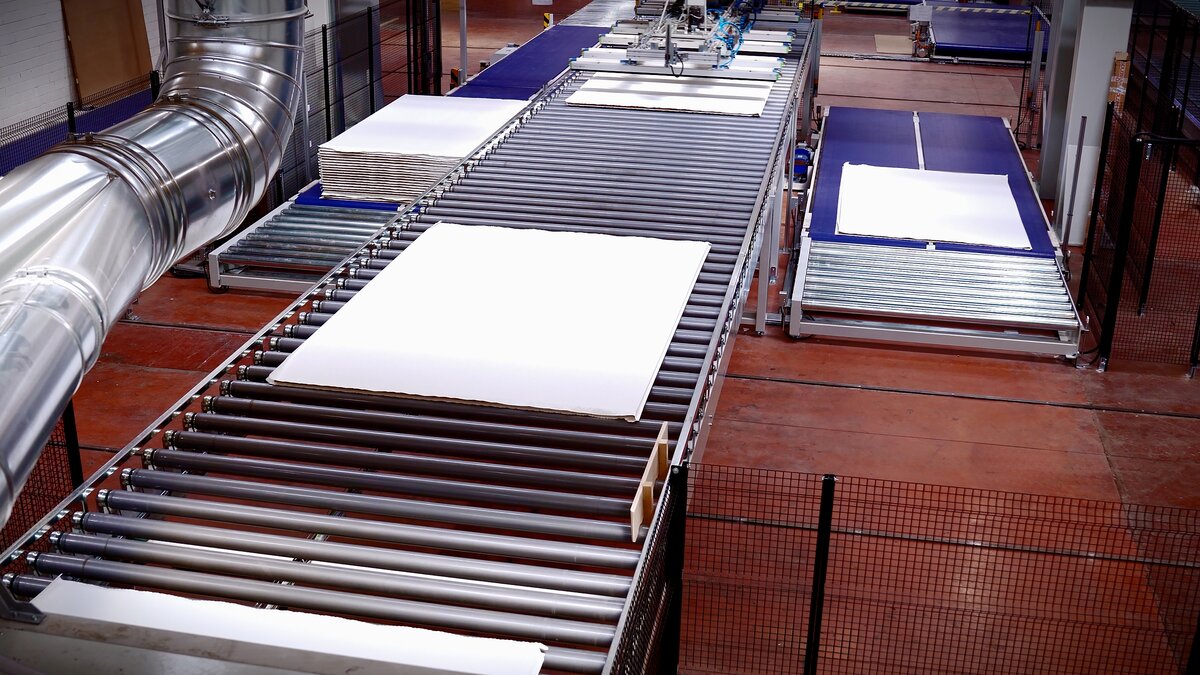

Top and cover insertion

Automatic insertion of top and cover into the honeycomb panel, with precise positioning and optimized gluing. The process guarantees structural solidity, flatness and quality of the finished product.

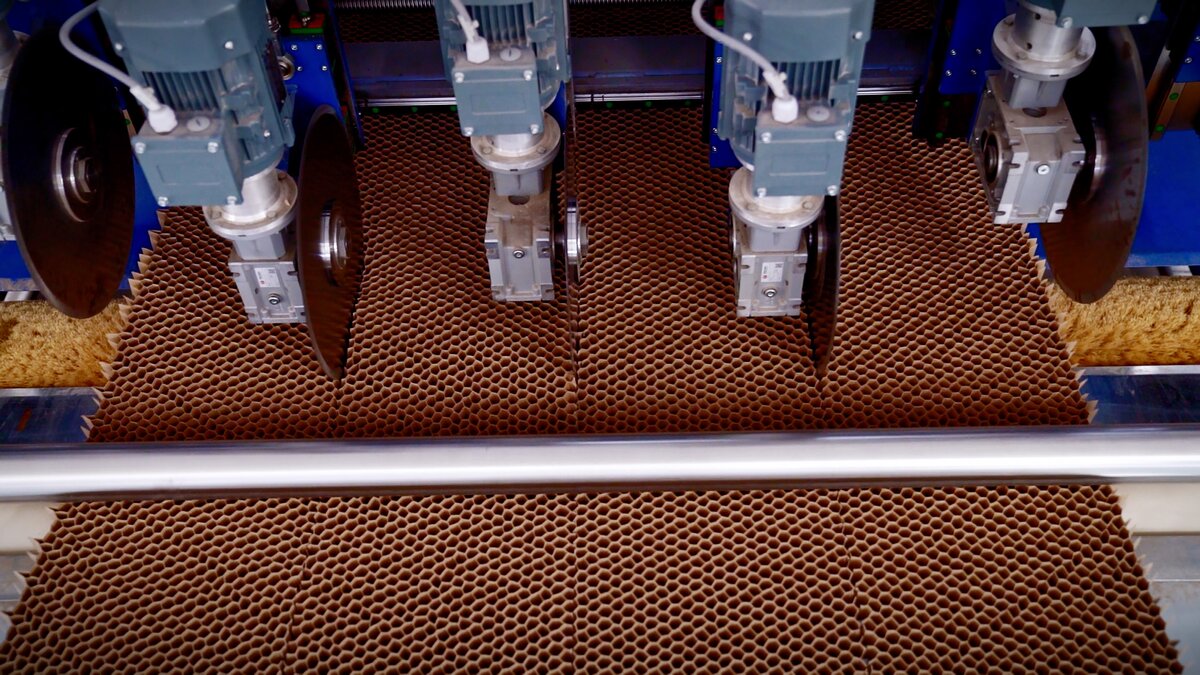

Sectioning

Precise cutting of the material to eliminate excess and perfectly finish all sides of the product.

Final Palletizing

Pallet creation with automatic or robotic systems. The finished product is stacked ready for the next destination.

Discover Tecno Logica’s solutions

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Stile cutting

Precise cutting of materials for the construction of the honeycomb panel, ensuring waste optimization and maximum production efficiency. The process ensures high quality and uniformity of the components.

Honeycomb expansion, gluing and handling

Expansion, gluing and handling of the honeycomb for the construction of light panels. The process guarantees a uniform opening of the honeycomb structure and precise positioning, ensuring stability and lightness to the finished panel.

Top and cover insertion

Automatic insertion of top and cover into the honeycomb panel, with precise positioning and optimized gluing. The process guarantees structural solidity, flatness and quality of the finished product.

Sectioning

Precise cutting of the material to eliminate excess and perfectly finish all sides of the product.

Final Palletizing

Pallet creation with automatic or robotic systems. The finished product is stacked ready for the next destination.

Discover Tecno Logica’s solutions

Discover more applications for the Wood sector

Doors internal/external

Manufacture plants for the production and/or processing of door panels, guaranteeing excellent performance and maximum adaptability to the different needs of the industry

Laminated tops

Laminate countertops are a key component of modern furniture, where aesthetics and durability come together harmoniously

Drawer

In traditional production lines, the assembly of drawers often requires significant costs and risks related to operational variability

We are ready to listen, analyze and build tailor-made solutions for you.

Fill out the form below and one of our experts will contact you as soon as possible.