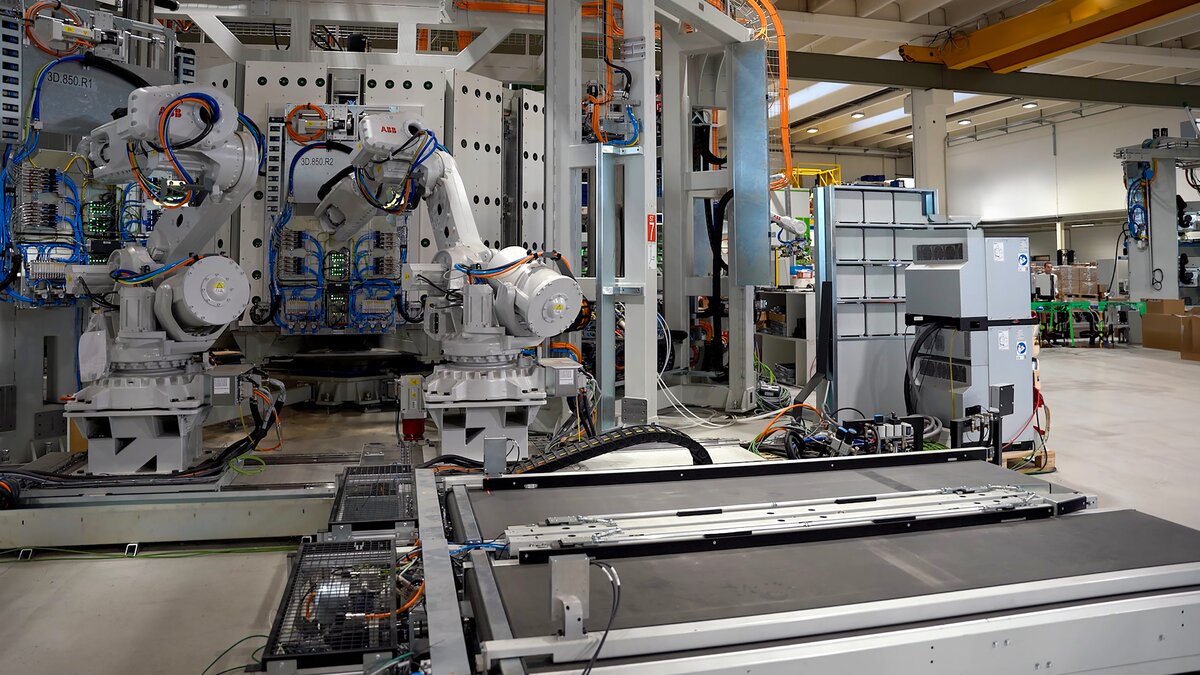

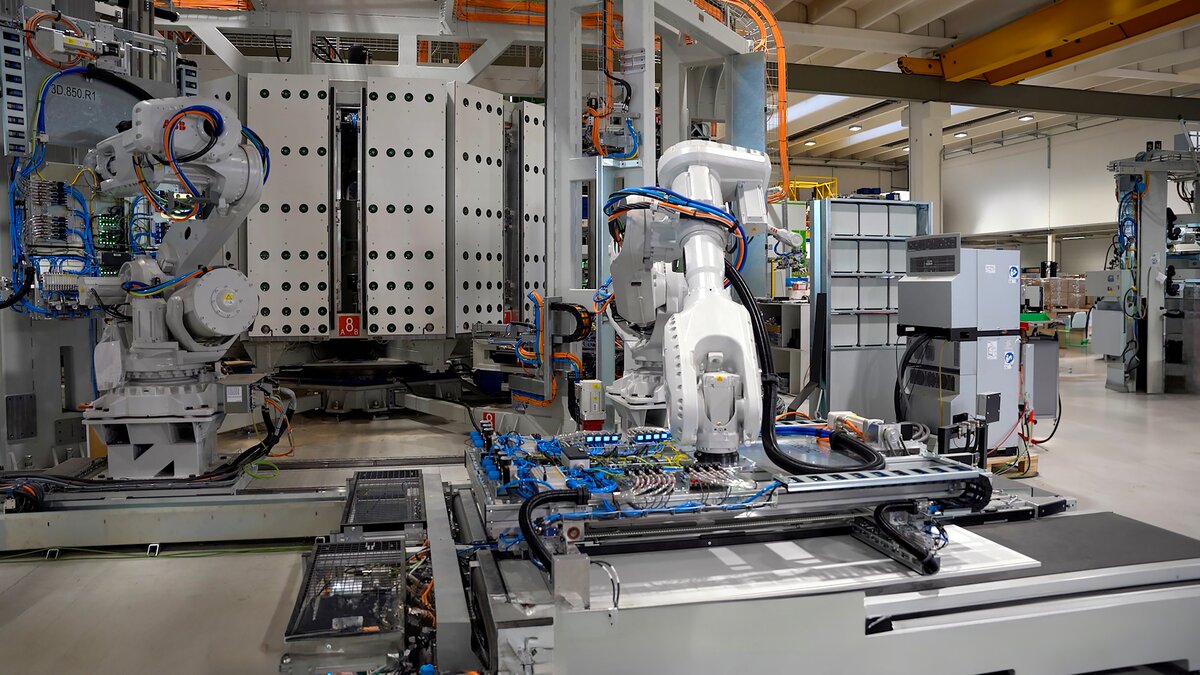

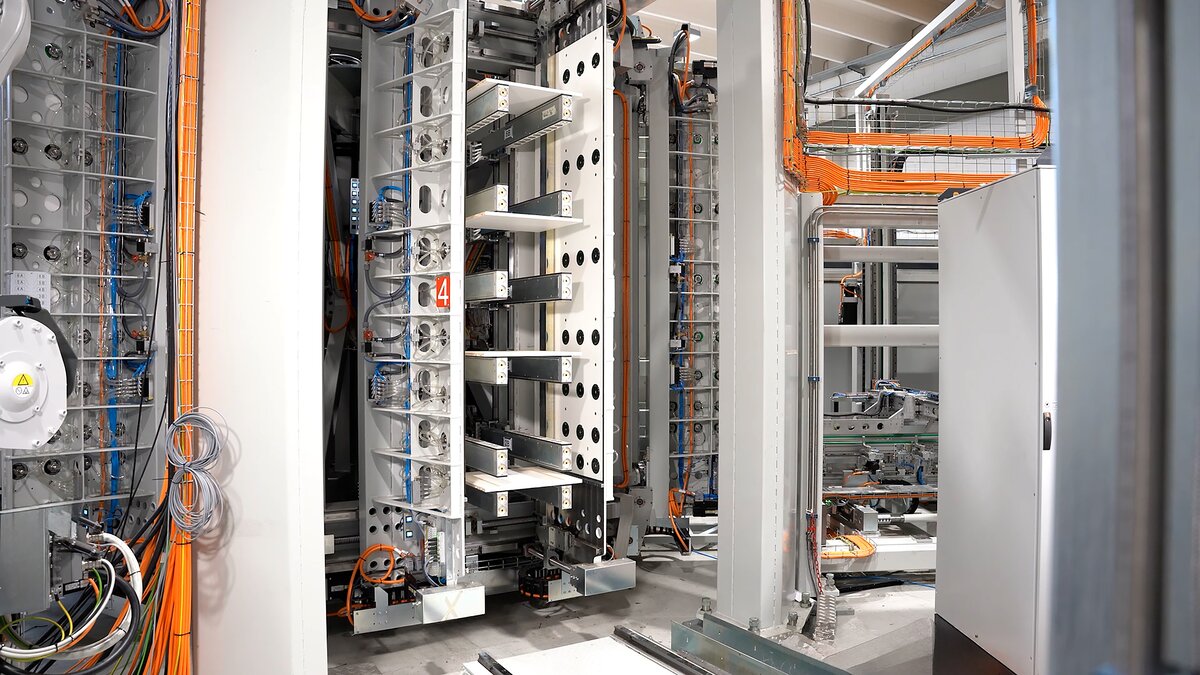

Our industrial automation and robotics solutions for modular furniture aim to make each stage of the production process more efficient and high-performing, thanks to the adoption of advanced technologies and integration between the various production steps.

- Full integration: automatic and integrated management of each step

- High performance: proven engineering solutions and business continuity for rapid return on investment.

- Production adaptability: versatile solutions capable of meeting different needs in terms of capacity, configuration and batch size.

We design custom systems tailored to every need.

Whether it's high-performance batch production or highly flexible systems for managing batch size one, our solutions integrate advanced technologies for drilling, milling, hardware insertion, assembly, and automated handling—ensuring an optimized production flow while minimizing waste.

Tecno Logica designs and implements automation solutions that transform the modular furniture production process, with a special focus on the kitchen and bathroom furniture sector. Thanks to the combination of advanced technologies, multi-sector expertise and the adaptability and modularity-oriented approach, the systems are designed to meet different needs in terms of space, process configuration and production capacity, ensuring a suitable solution for every industrial need.

Our technologies guarantee high performance, maximum precision and reliability within the production mix: from drilling and milling to managing the automatic insertion of dowels and hardware, to the innovative fully automatic cabinet assembly system, not forgetting the important and delicate material preparation phase. Our goal is to accompany the woodworking sector towards a new era of industrial and technological development, proposing automation solutions that increase competitiveness and production efficiency by integrating different processes: from more traditional processing such as the drilling of sides and doweling of horizontal elements, to extremely complex and automated ones, such as the automatic assembly of doors to cabinets or the insertion of drawers into them.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

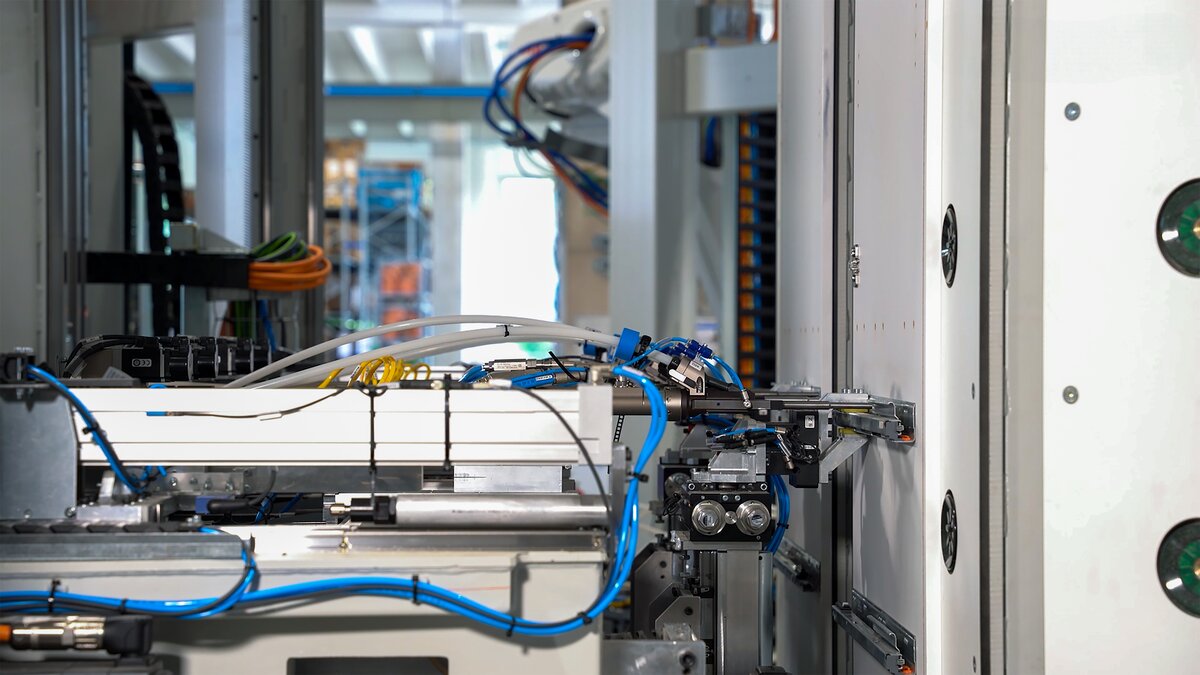

Drilling

High precision drilling with automatic systems, configurable for different applications and materials, ensuring speed, repeatability and quality of the process. Particular attention is paid to the dust extraction systems, ensuring maximum cleanliness of the workpiece and the surrounding environment.

Milling

High precision milling with automatic systems configurable for different applications. We guarantee speed, repeatability and quality of the process, integrating high performance suction solutions to keep the workpiece and the surrounding environment clean.

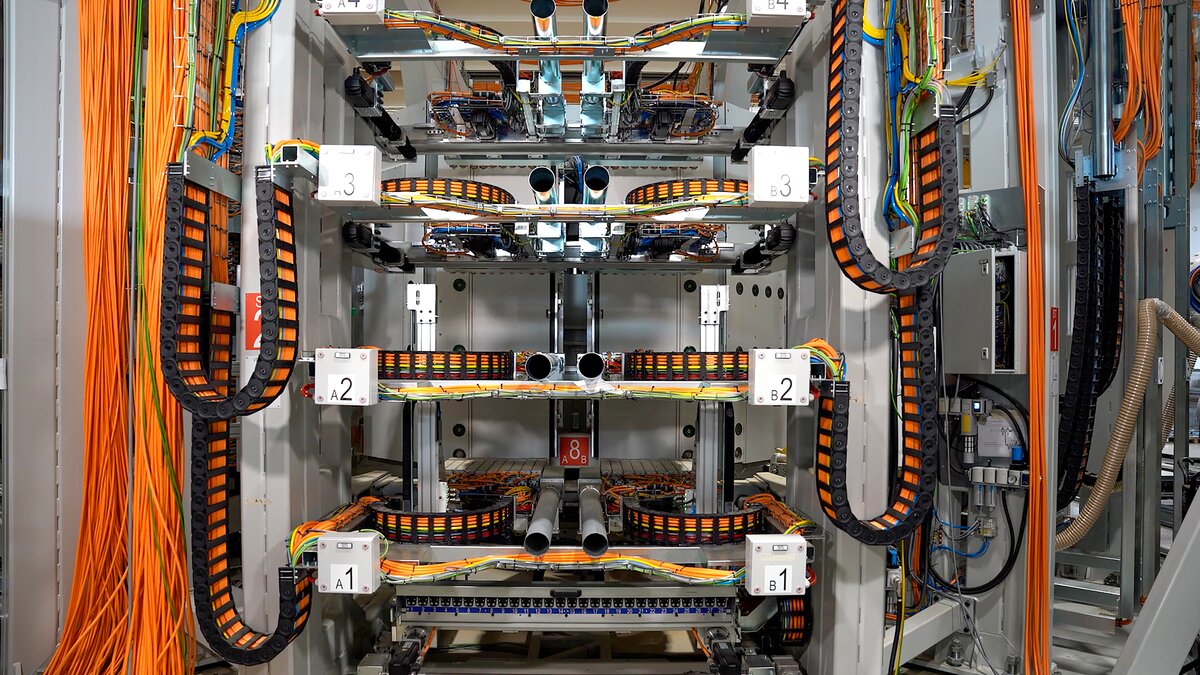

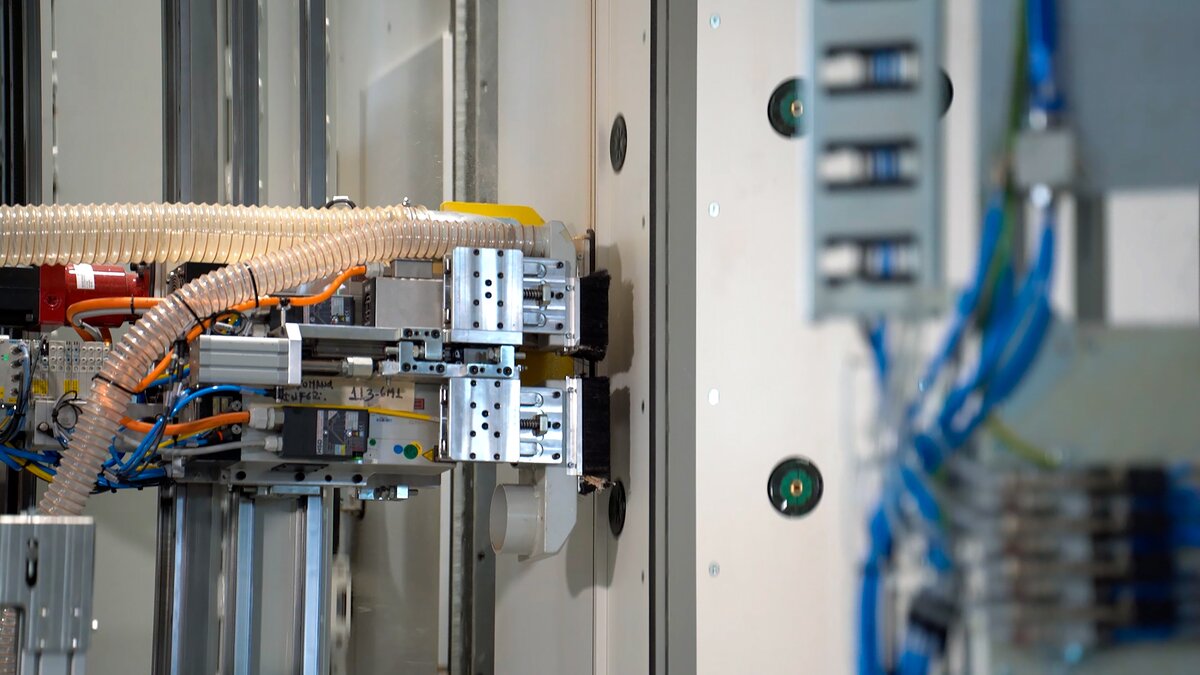

Hardware & Dowel Insertion

Automatic insertion of dowels and hardware for cabinet construction, including hinge bases, drawer rails, cabinet hangars, shelf supports, and front components such as hinges or drawer pulls. Our systems guarantee maximum precision and adaptability, with inserter groups designed to ensure maximum reliability, even in the most intensive production cycles.

Discover Tecno Logica’s solutions

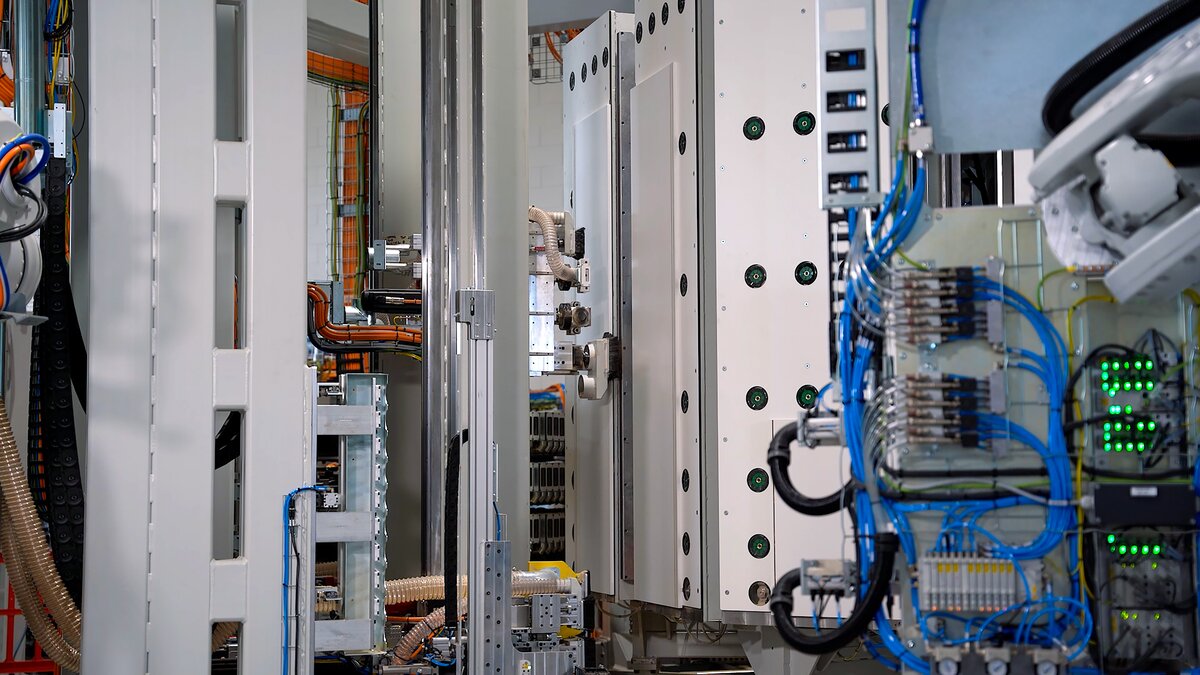

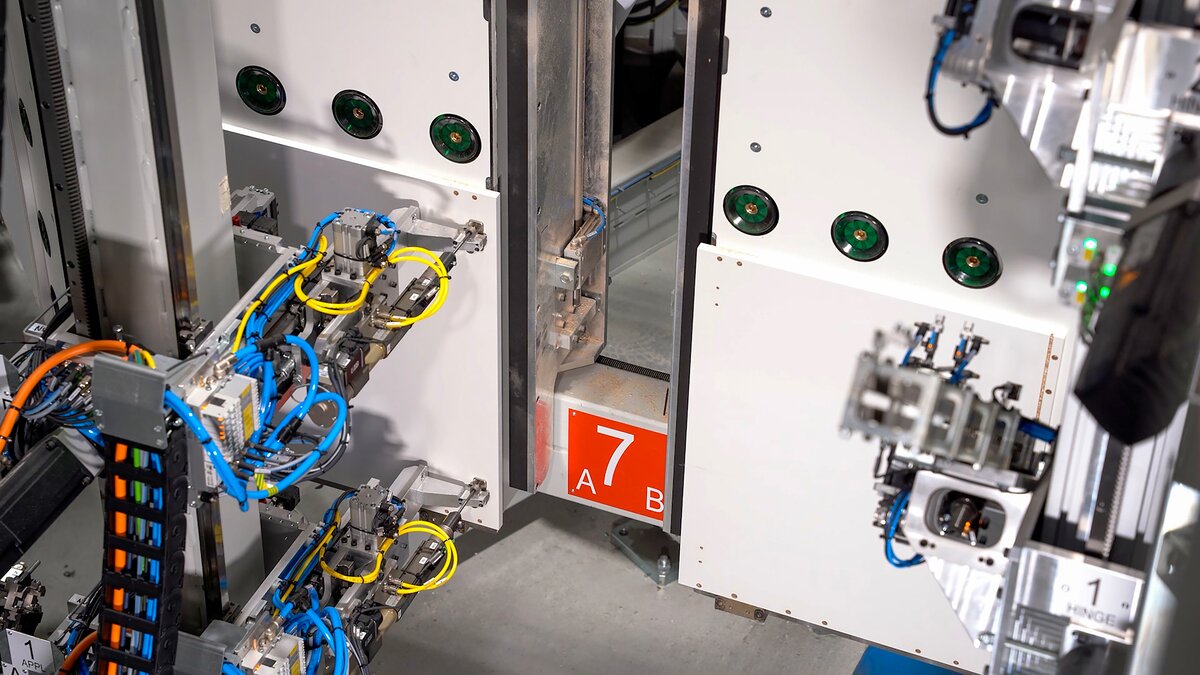

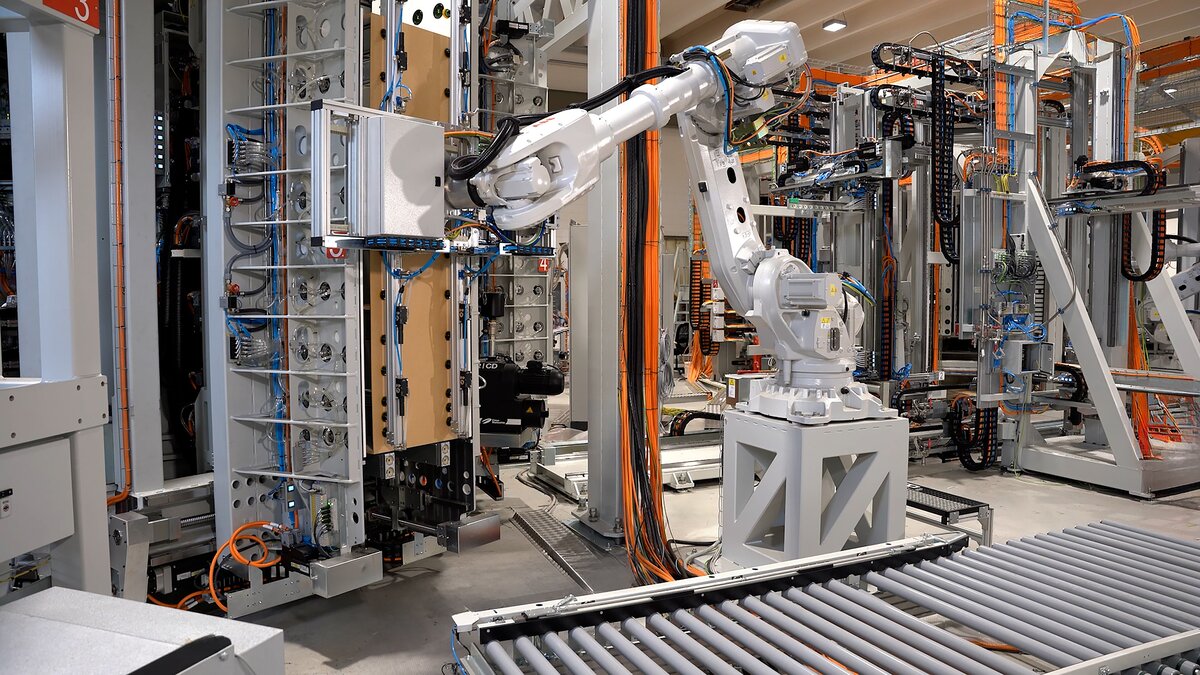

Assembly

Automatic cabinet assembly through the handling of all its components: side panels, horizontal elements, and back panel are positioned, pressed, and stapled when required. The process ensures a solid and precise joint.

Automatic Drawer Insertion

In the automatic cabinet production process, no operation is excluded: even the insertion of the drawers is completely automated, thus completing the cabinet. An innovation that redefines production standards.

Automatic Door Insertion

In the automatic cabinet production process, no operation is excluded: even the assembly of the door on the assembled cabinet is completely automated, thus completing the product. An innovation that redefines production standards

Packaging

In the cabinet production flow, automation extends to the packaging phase, ensuring a fully integrated process. Automated order sorting allows efficient management of palletization and package accumulation, optimizing end-of-line logistics.

Discover Tecno Logica’s solutions

Discover more applications for the Wood sector

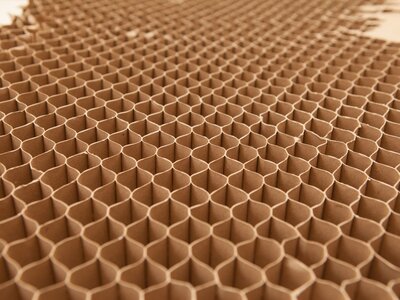

Honeycomb flat panel

The hollow-core panel represents a versatile and lightweight solution for the furniture and door sector

Doors internal/external

Manufacture plants for the production and/or processing of door panels, guaranteeing excellent performance and maximum adaptability to the different needs of the industry

Laminated tops

Laminate countertops are a key component of modern furniture, where aesthetics and durability come together harmoniously

We are ready to listen, analyze and build tailor-made solutions for you.

Fill out the form below and one of our experts will contact you as soon as possible.