Our applications

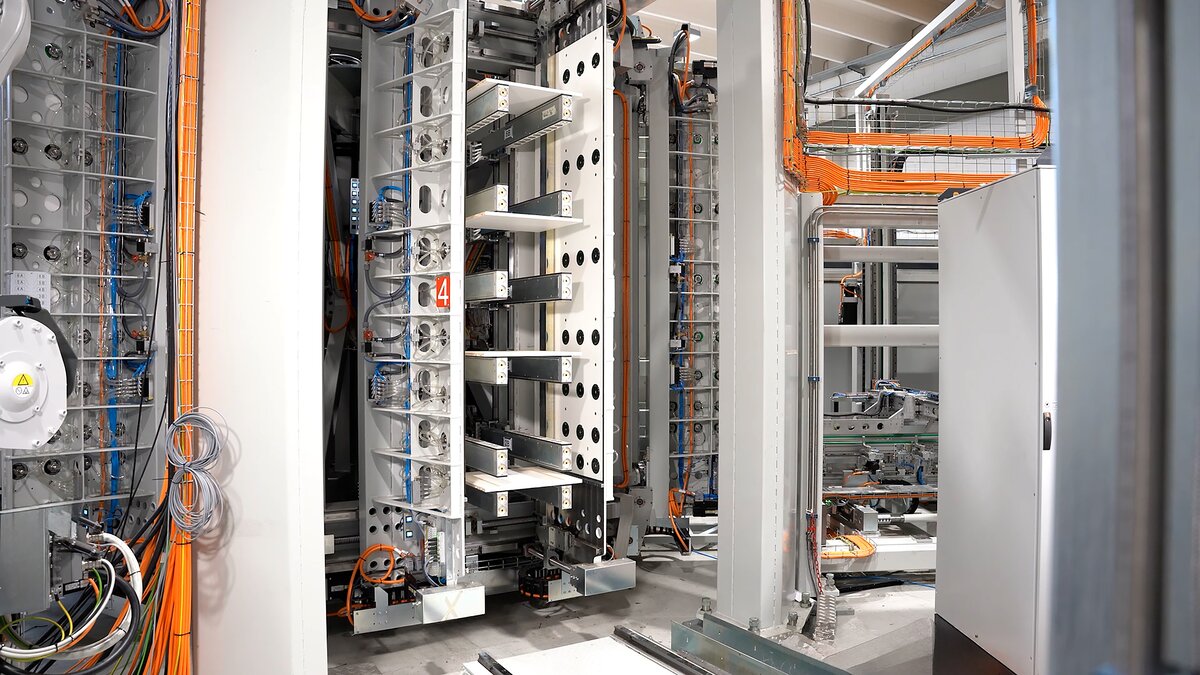

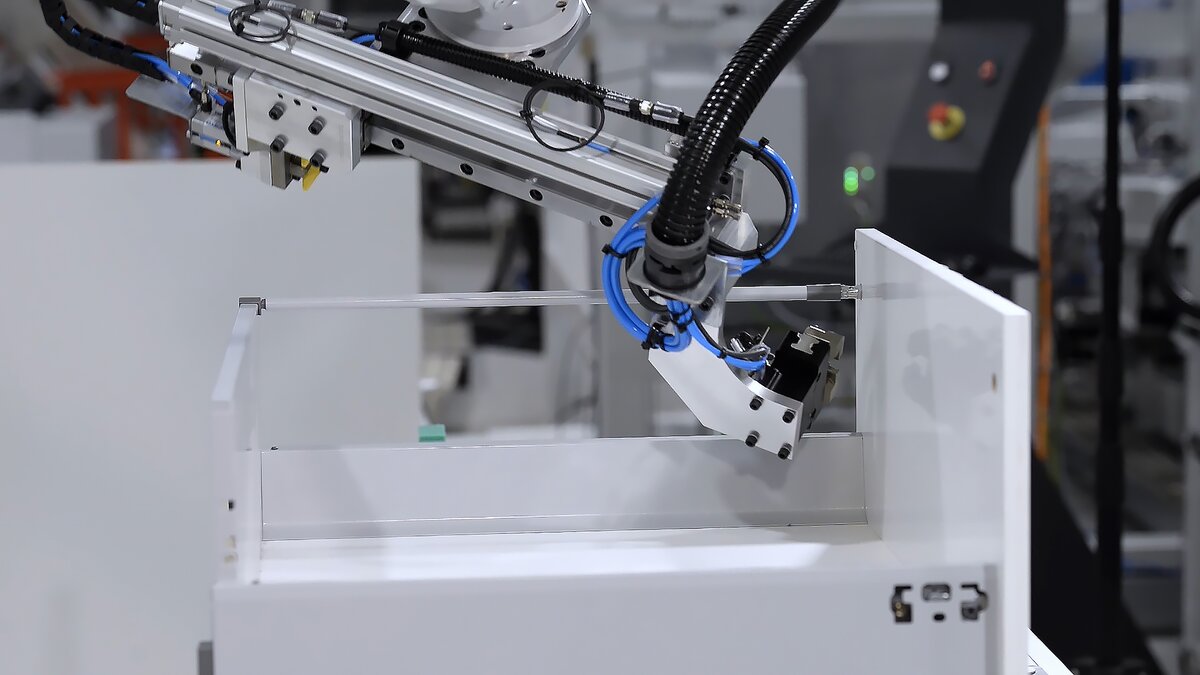

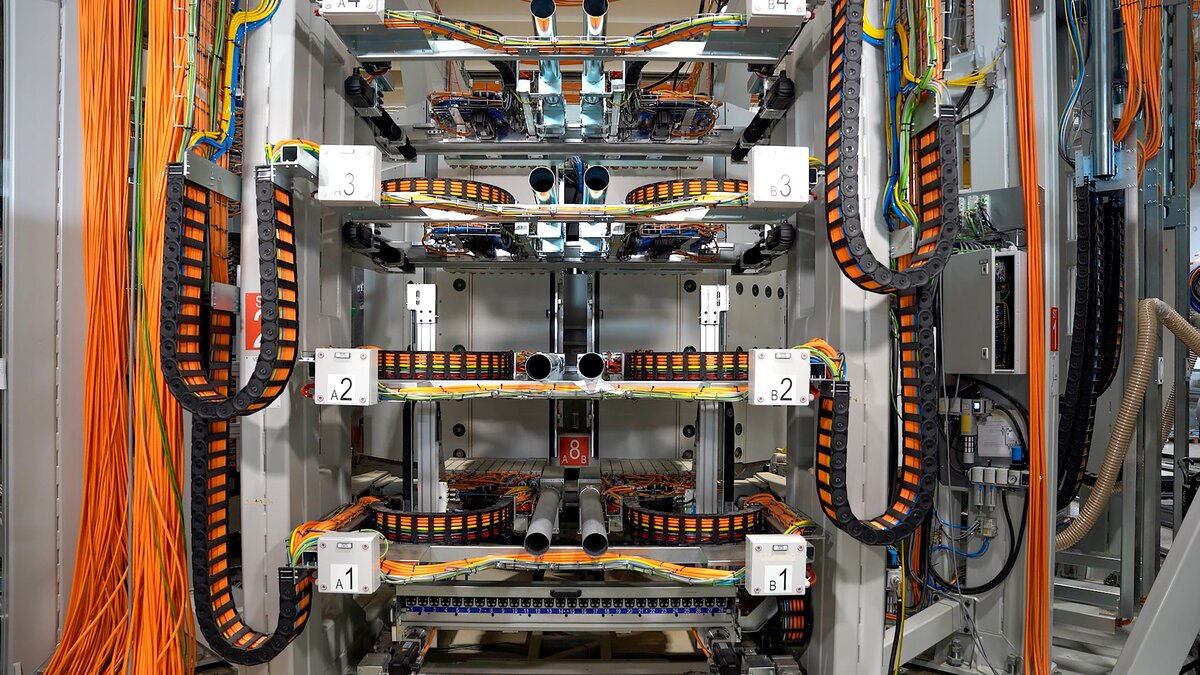

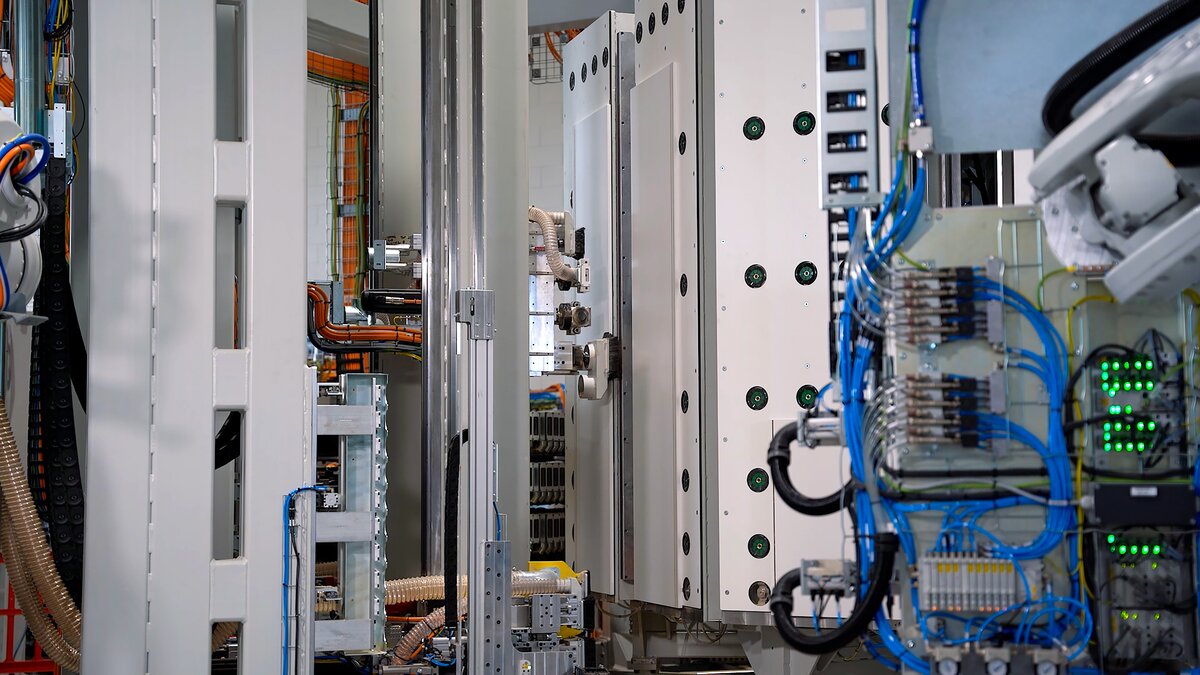

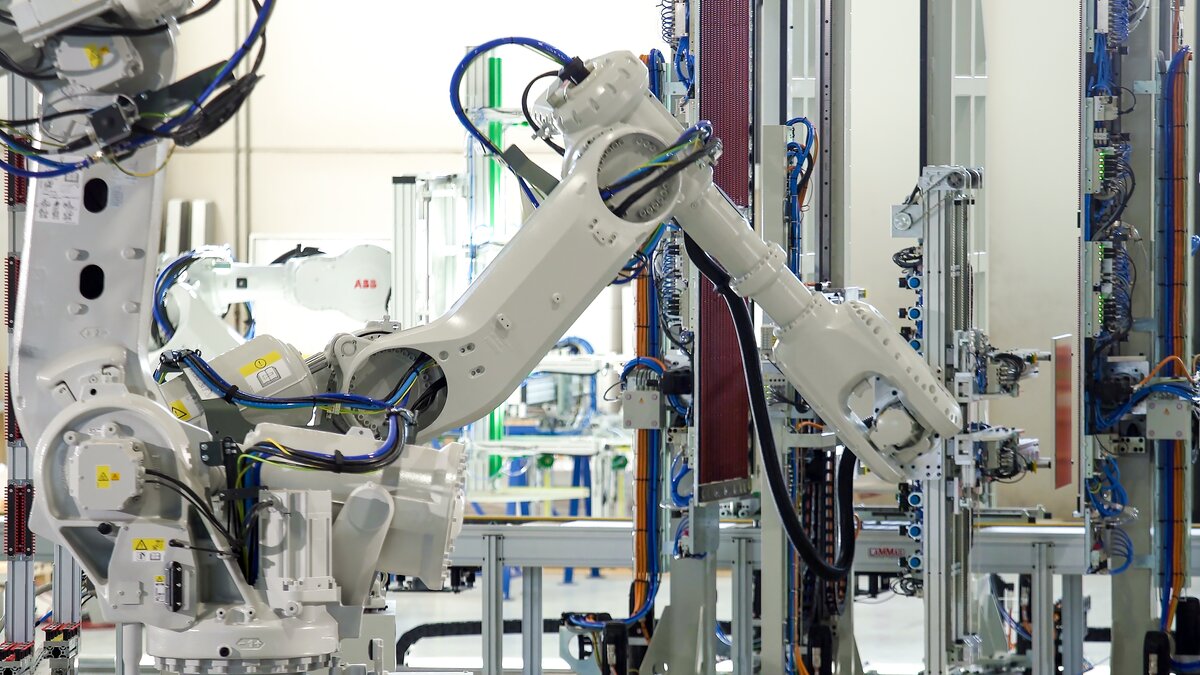

Cabinet box

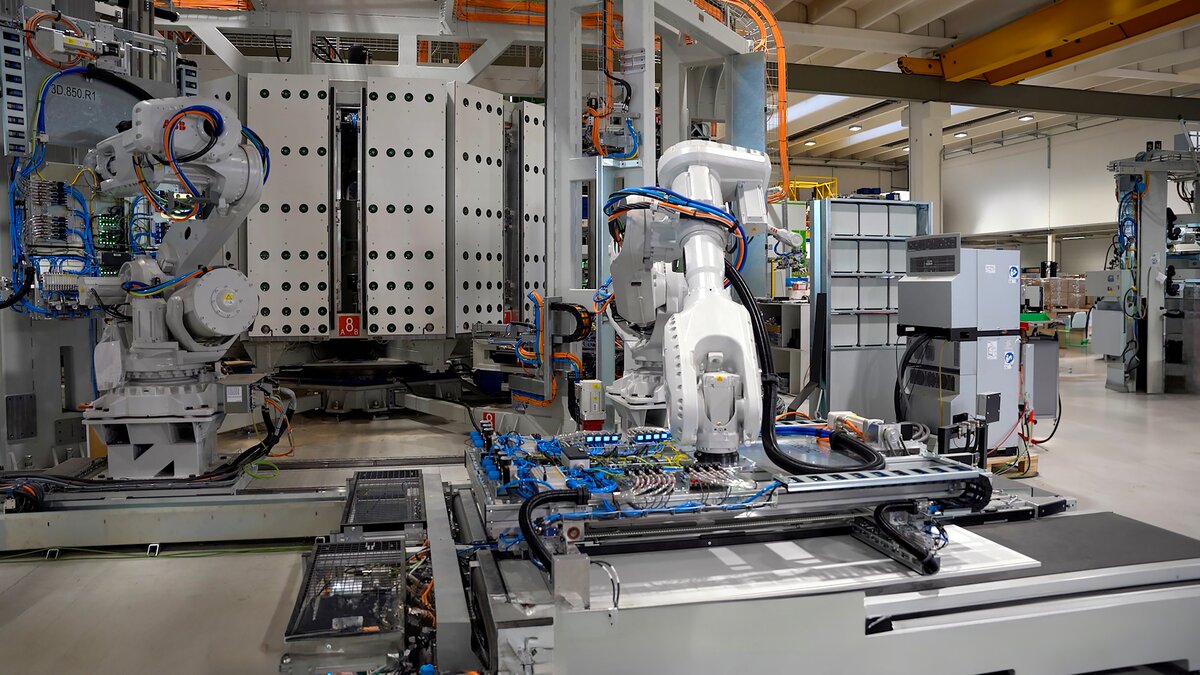

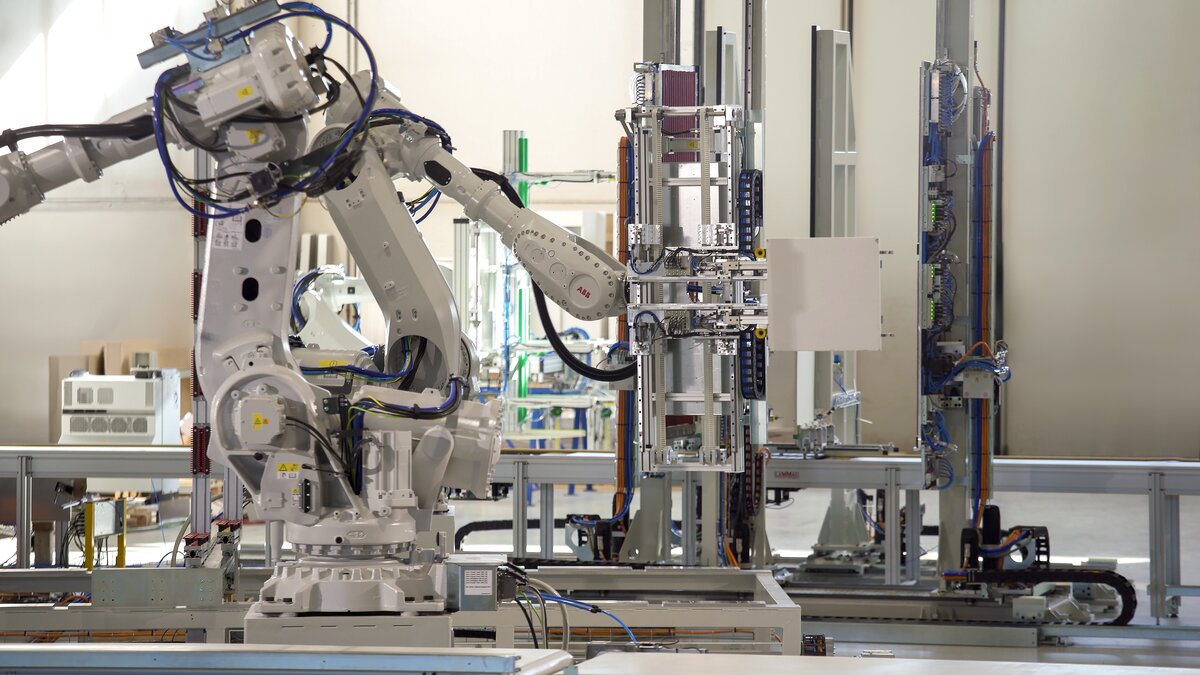

Our industrial automation and robotics solutions for modular furniture aim to make each stage of the production process more efficient and high-performing

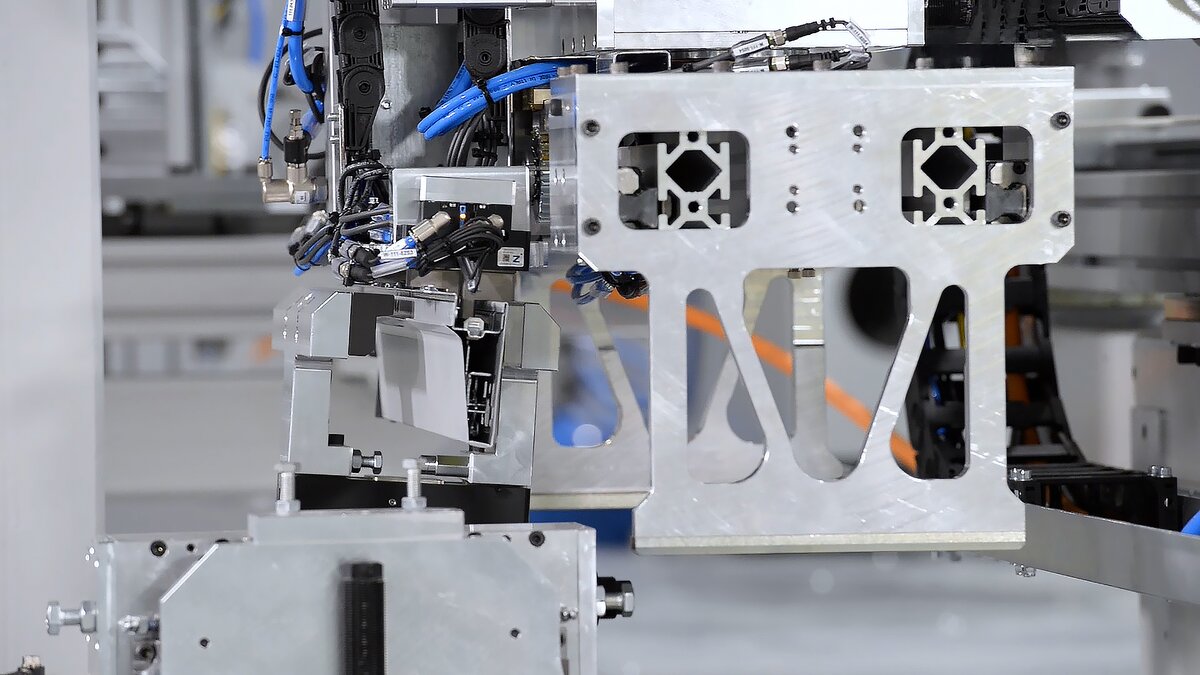

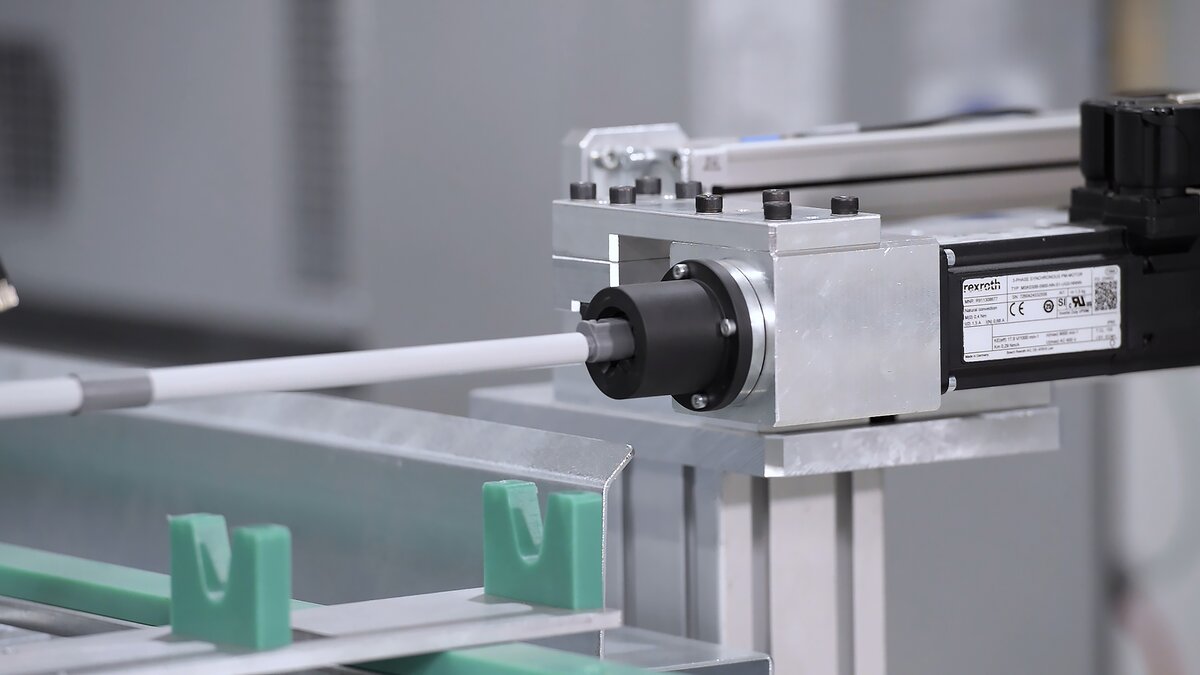

Drawer

In traditional production lines, the assembly of drawers often requires significant costs and risks related to operational variability

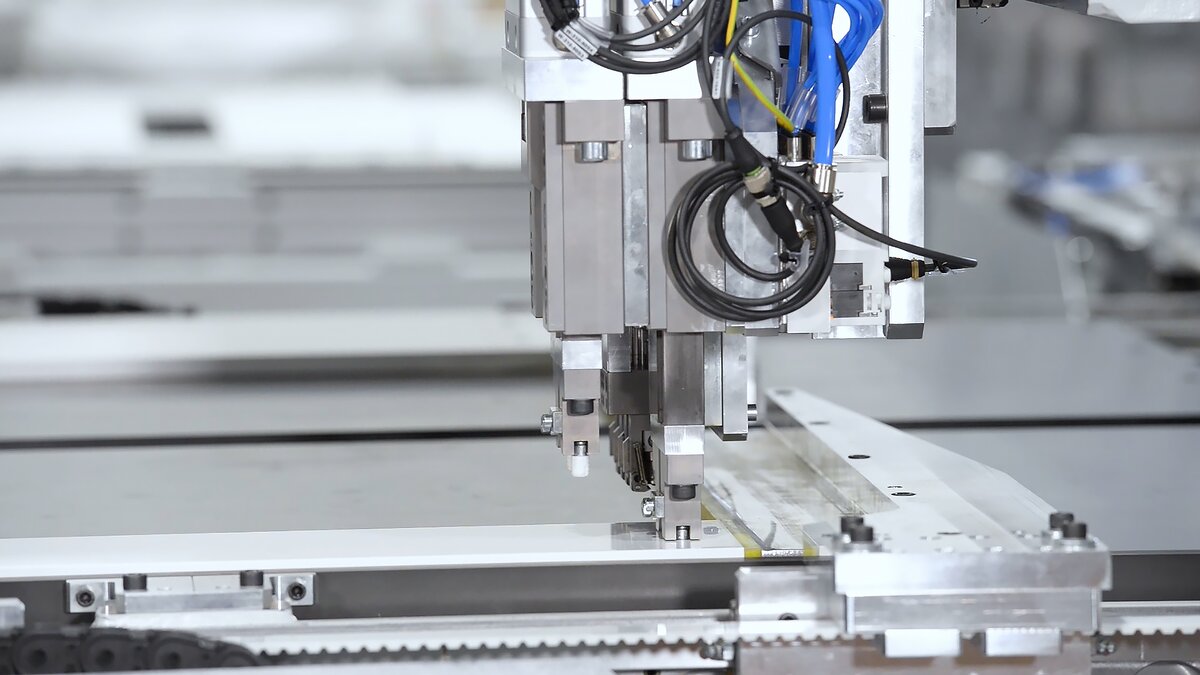

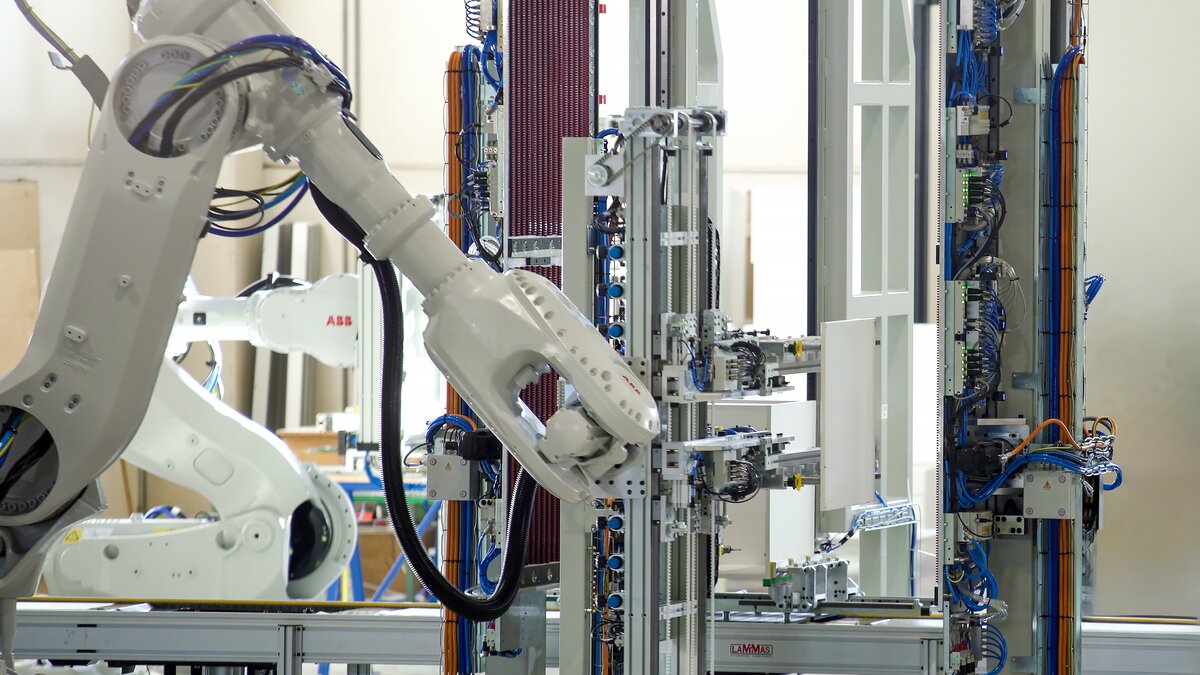

Cabinet doors

The door is the first visible element of a piece of furniture, the detail that defines the aesthetics and perceived quality of the final product

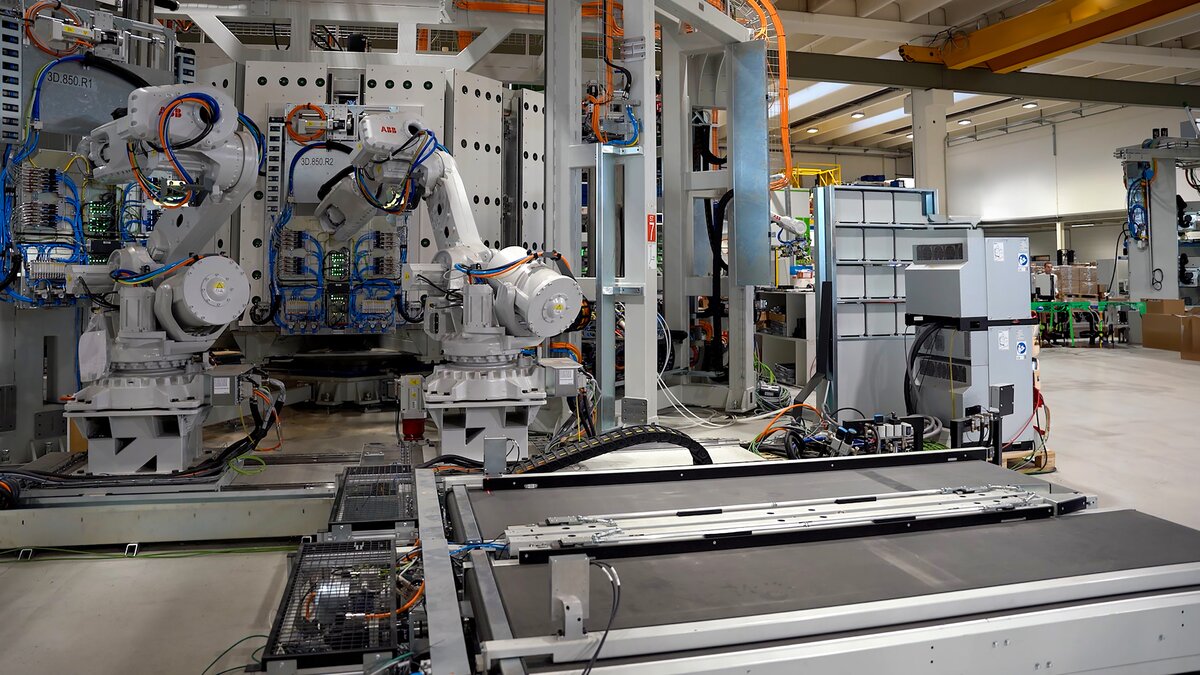

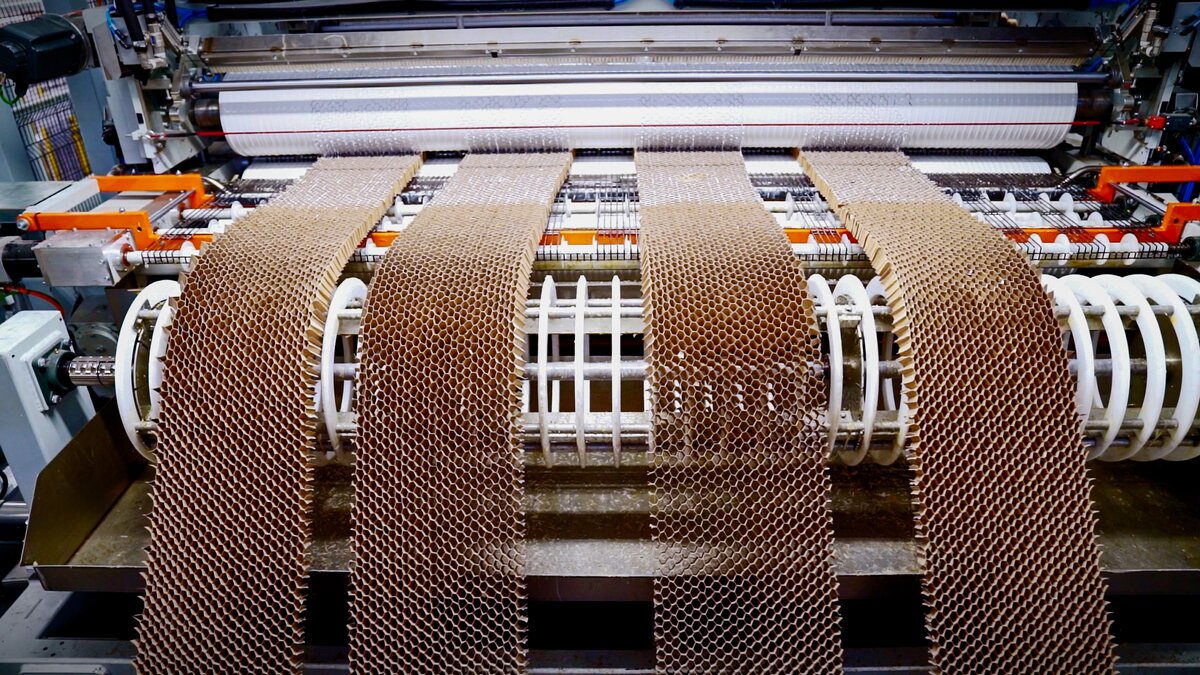

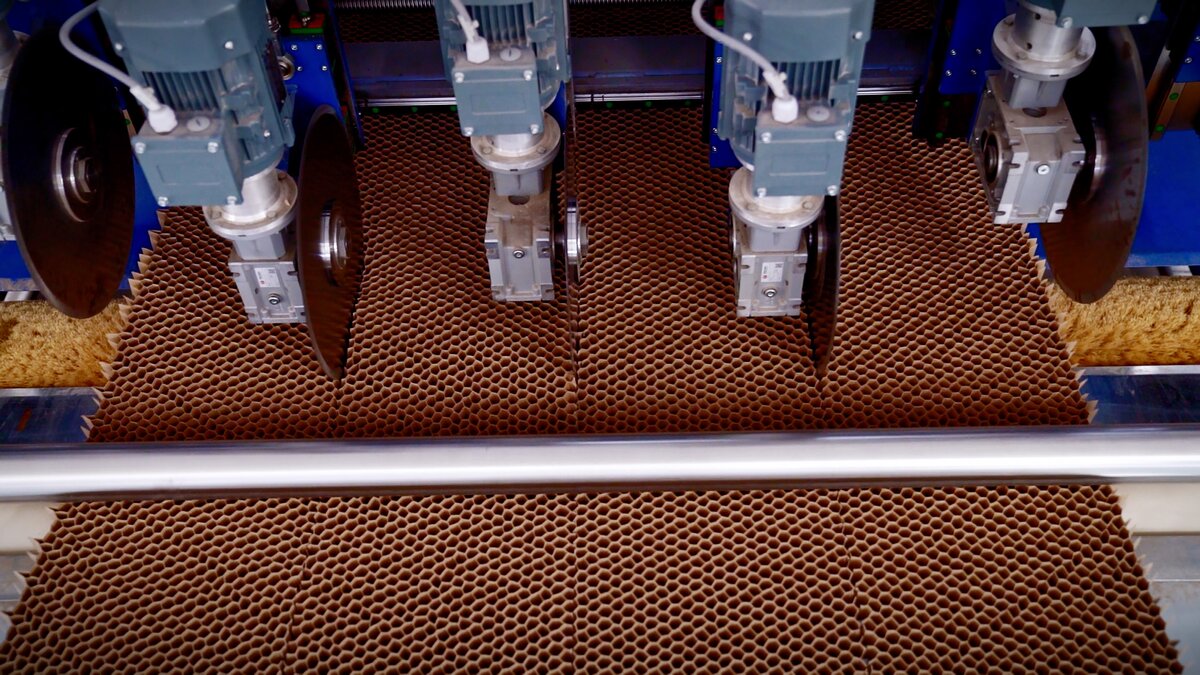

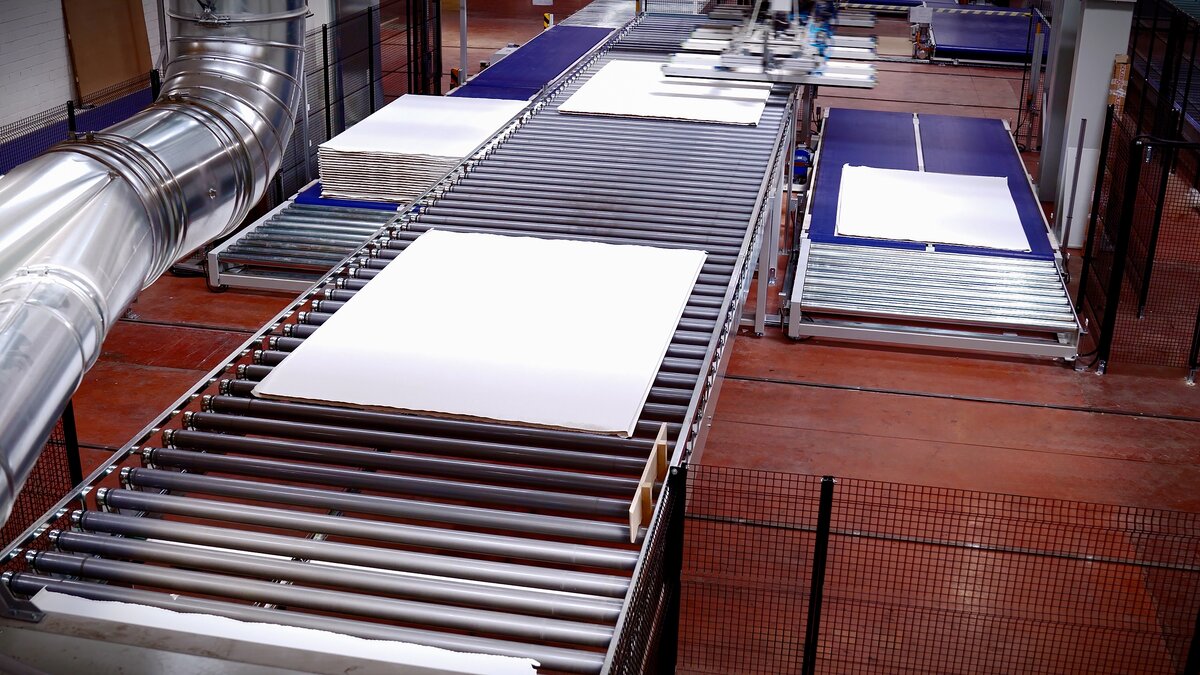

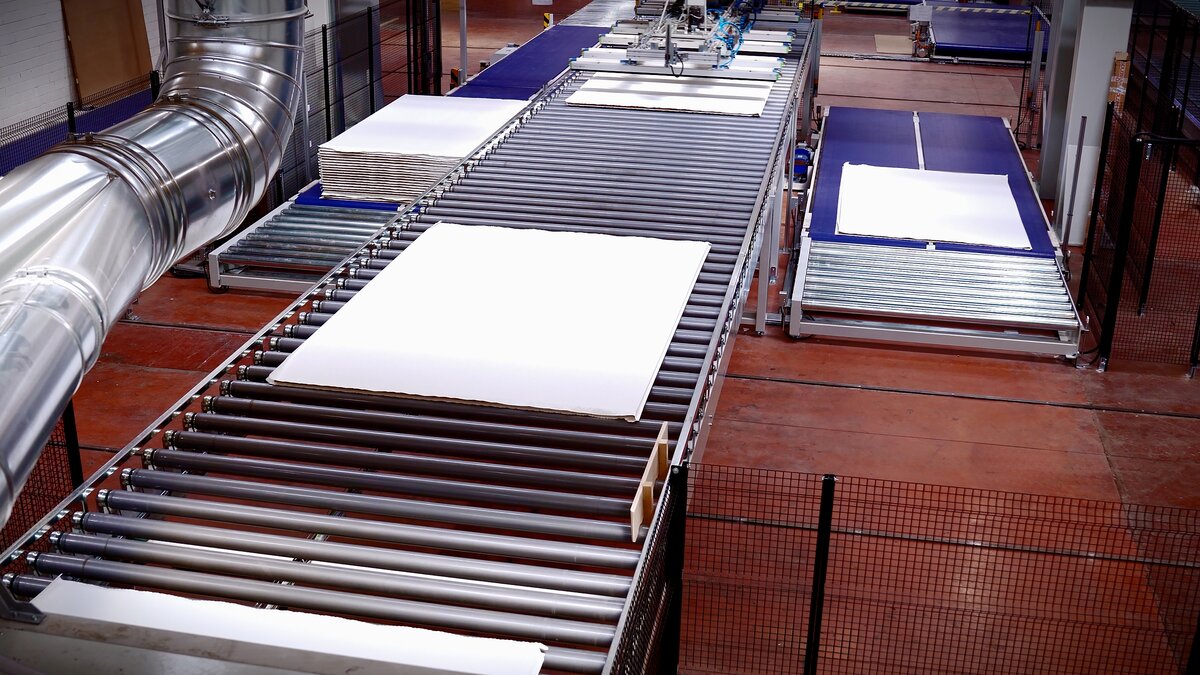

Honeycomb flat panel

The hollow-core panel represents a versatile and lightweight solution for the furniture and door sector

We design custom systems tailored to every need.

Our goal is to accompany the wood sector towards a concrete technological evolution, guaranteeing companies a rapid return on investment through solutions that increase productivity, reduce operating costs and improve the quality of the finished product.

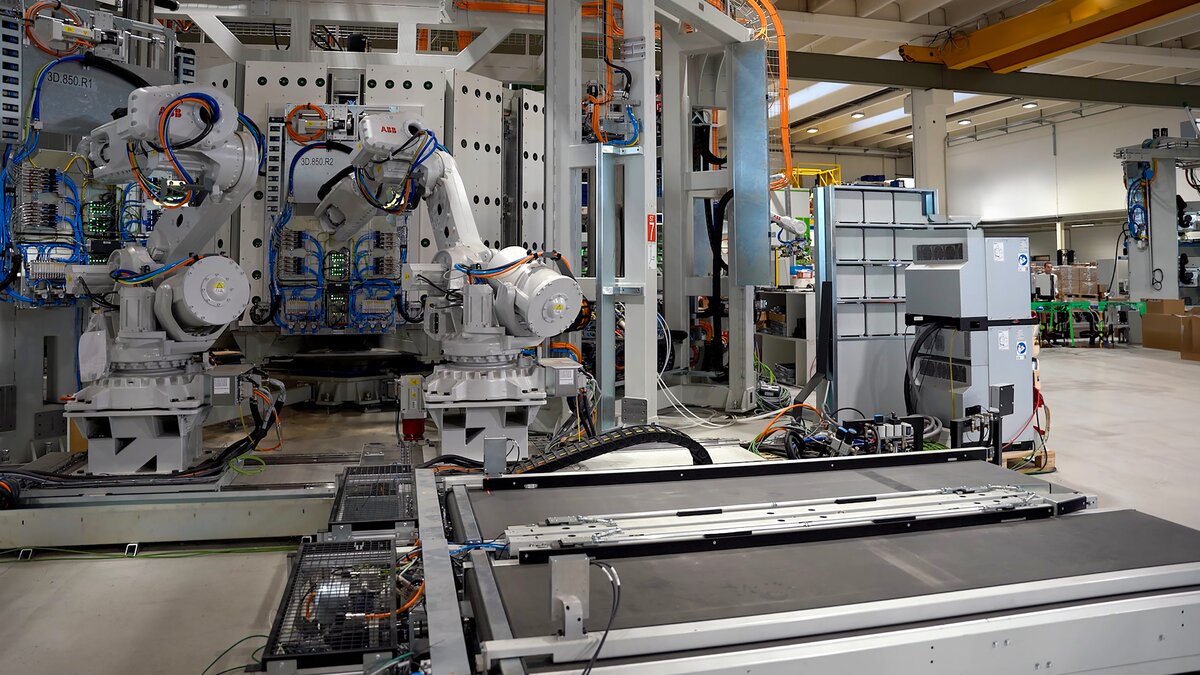

Tecno Logica designs and implements automation solutions that transform the modular furniture production process, with a special focus on the kitchen and bathroom furniture sector. Thanks to the combination of advanced technologies, multi-sector expertise and the adaptability and modularity-oriented approach, the systems are designed to meet different needs in terms of space, process configuration and production capacity, ensuring a suitable solution for every industrial need.

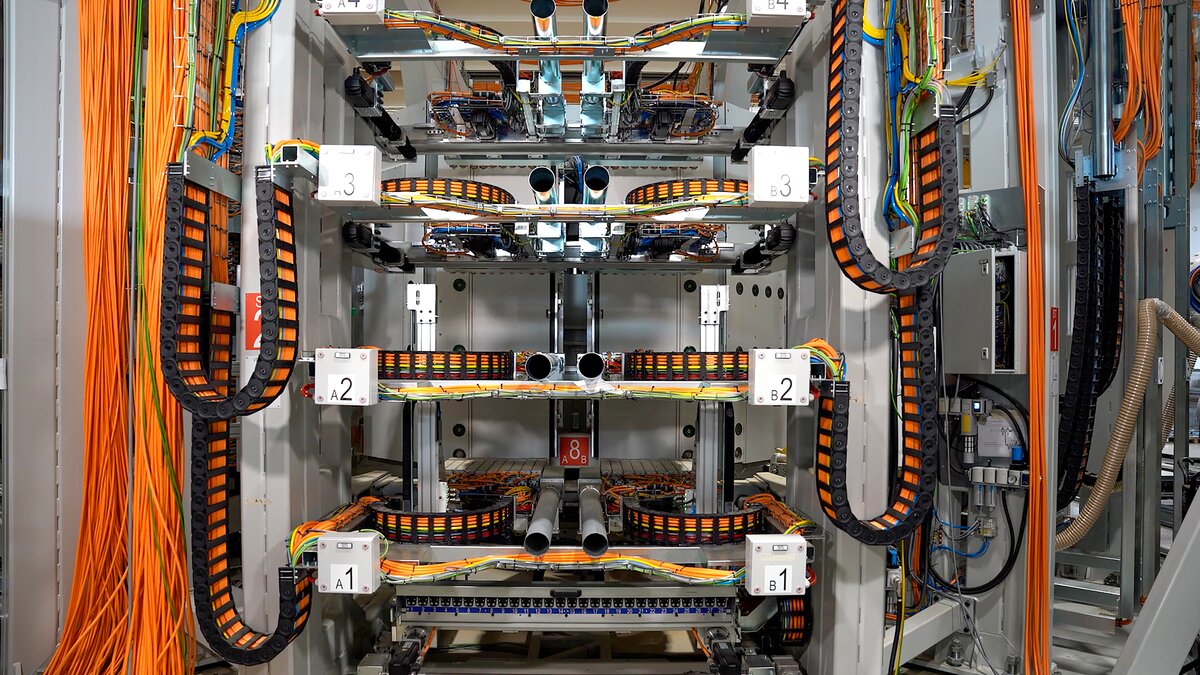

Our technologies guarantee high performance, maximum precision and reliability within the production mix: from drilling and milling to managing the automatic insertion of dowels and hardware, to the innovative fully automatic cabinet assembly system, not forgetting the important and delicate material preparation phase. Our goal is to accompany the woodworking sector towards a new era of industrial and technological development, proposing automation solutions that increase competitiveness and production efficiency by integrating different processes: from more traditional processing such as the drilling of sides and doweling of horizontal elements, to extremely complex and automated ones, such as the automatic assembly of doors to cabinets or the insertion of drawers into them.

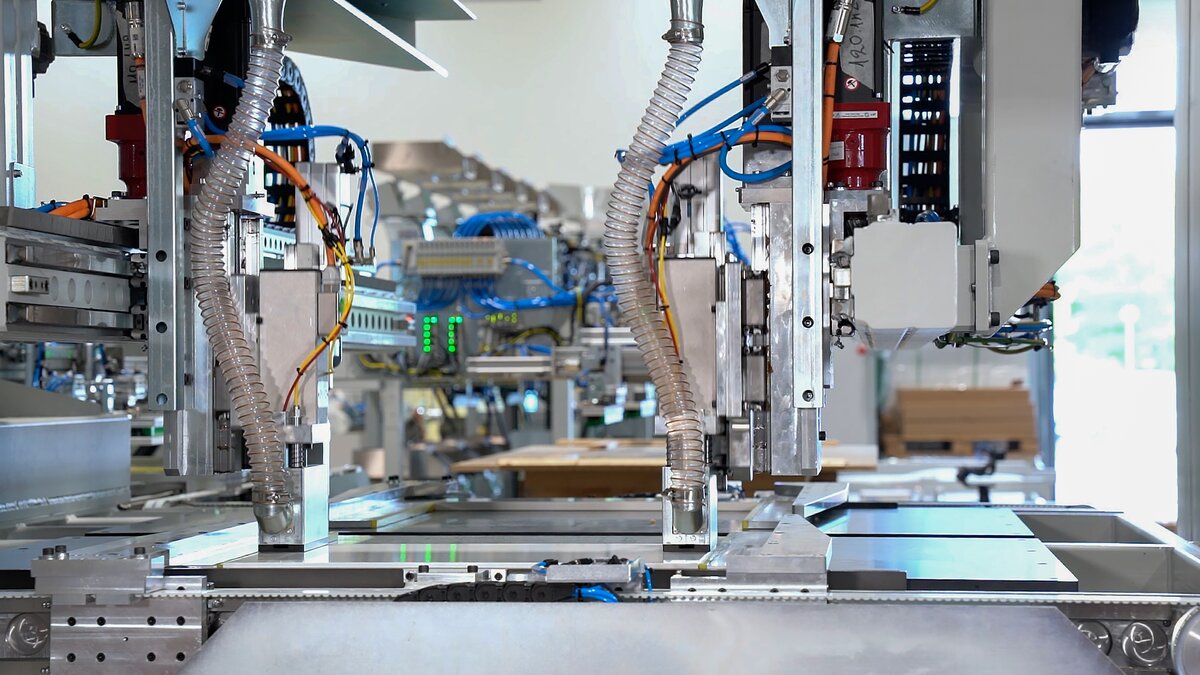

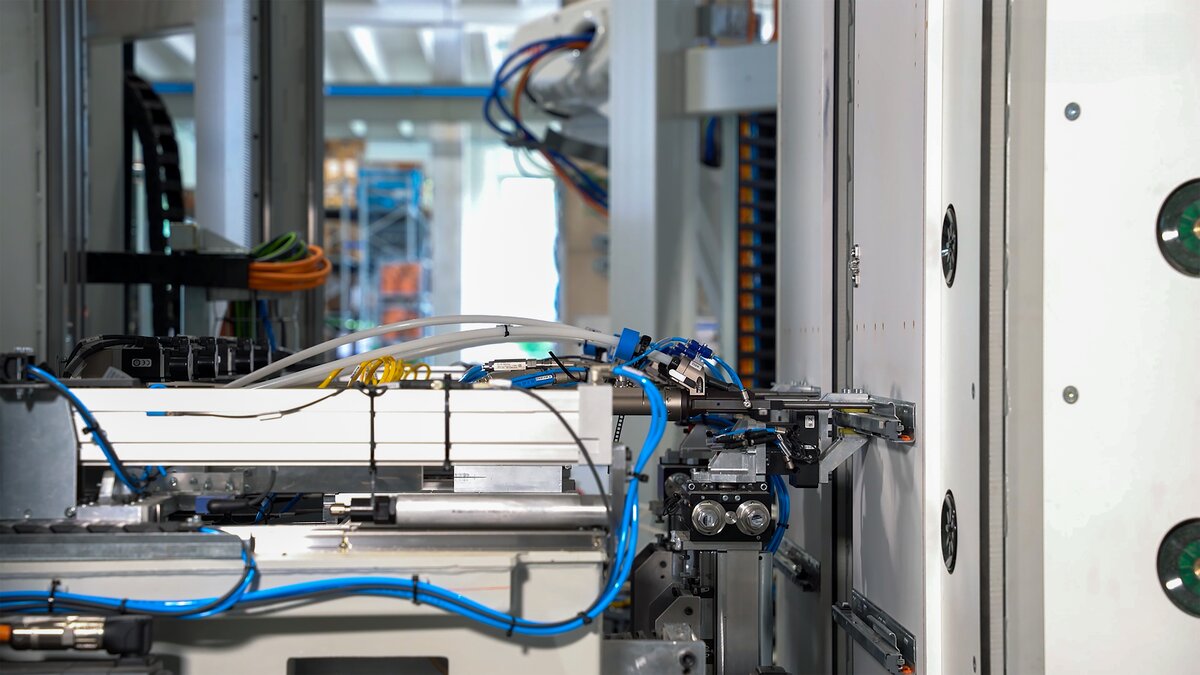

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Drilling

Milling

High precision milling with automatic systems configurable for different applications. We guarantee speed, repeatability and quality of the process, Integrating high-performance dust extraction solutions to keep both the workpiece and the surrounding environment clean.

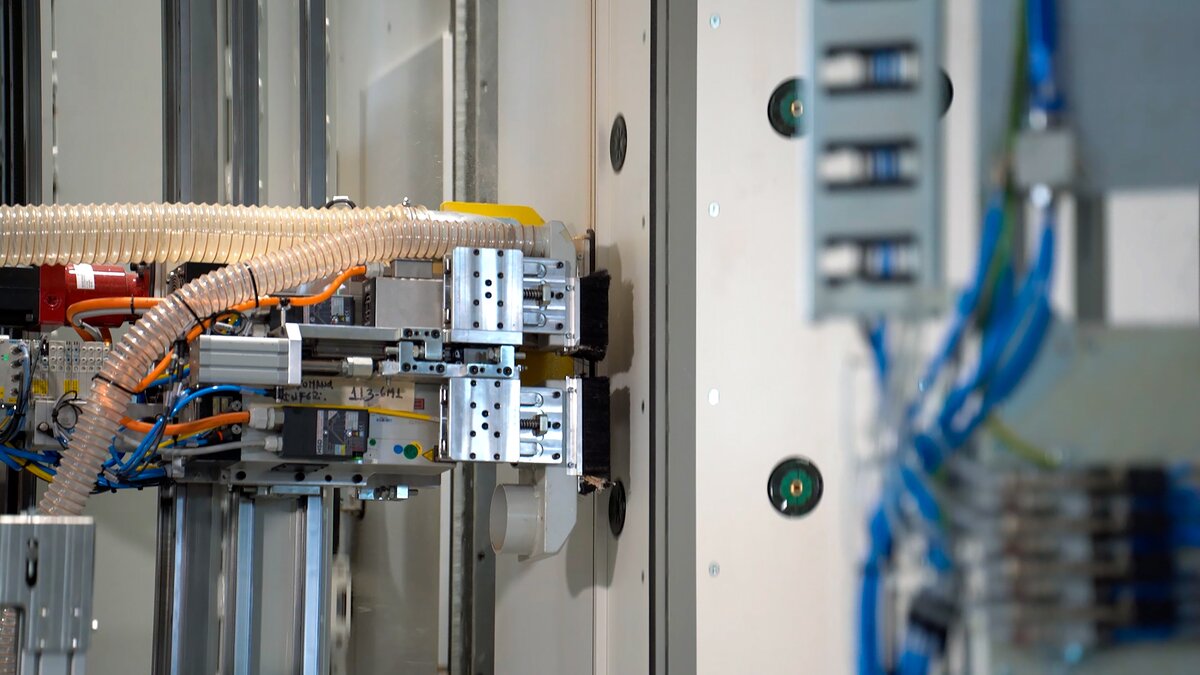

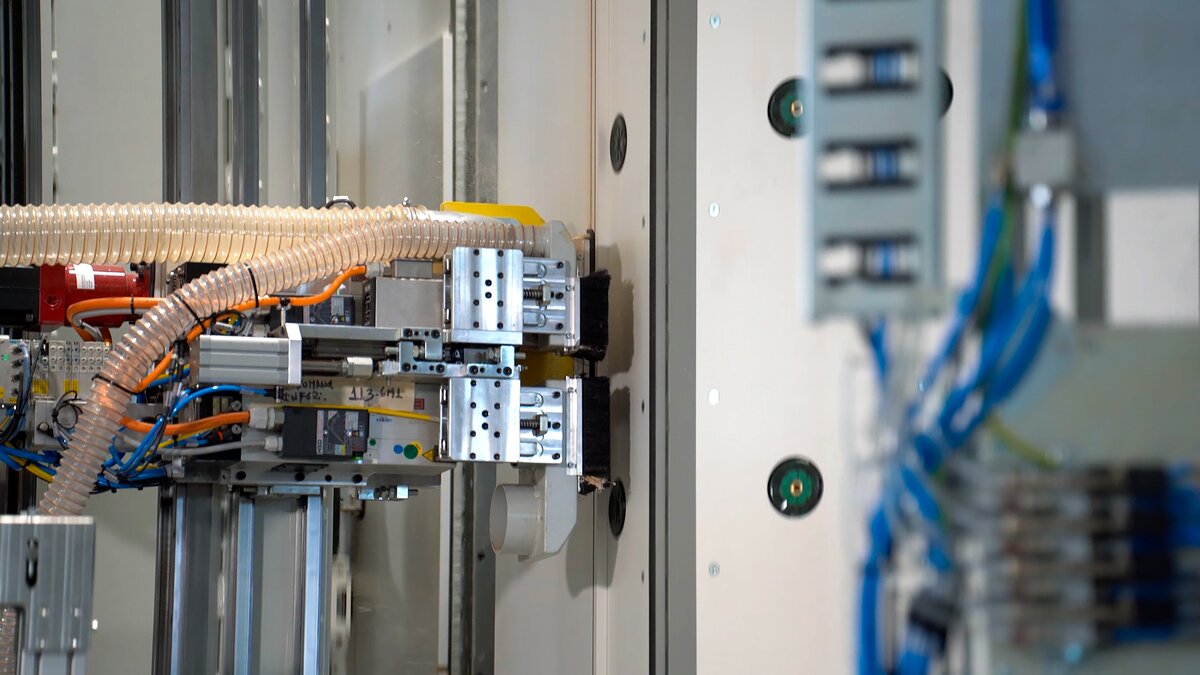

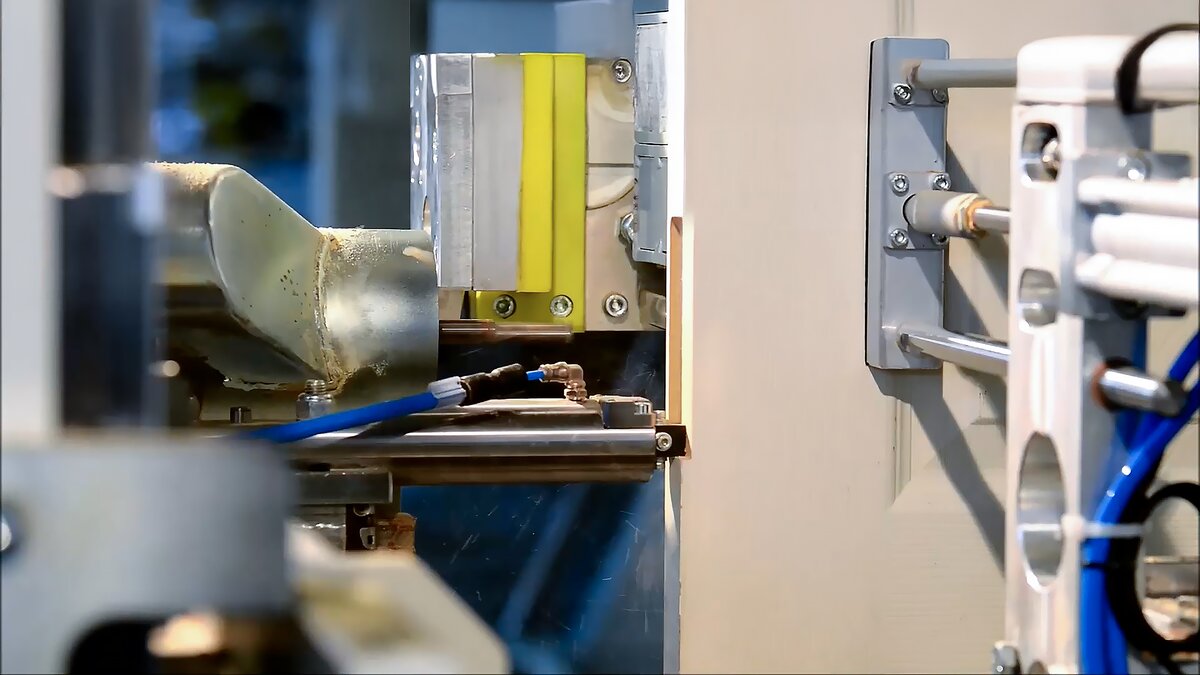

Hardware & Dowel Insertion

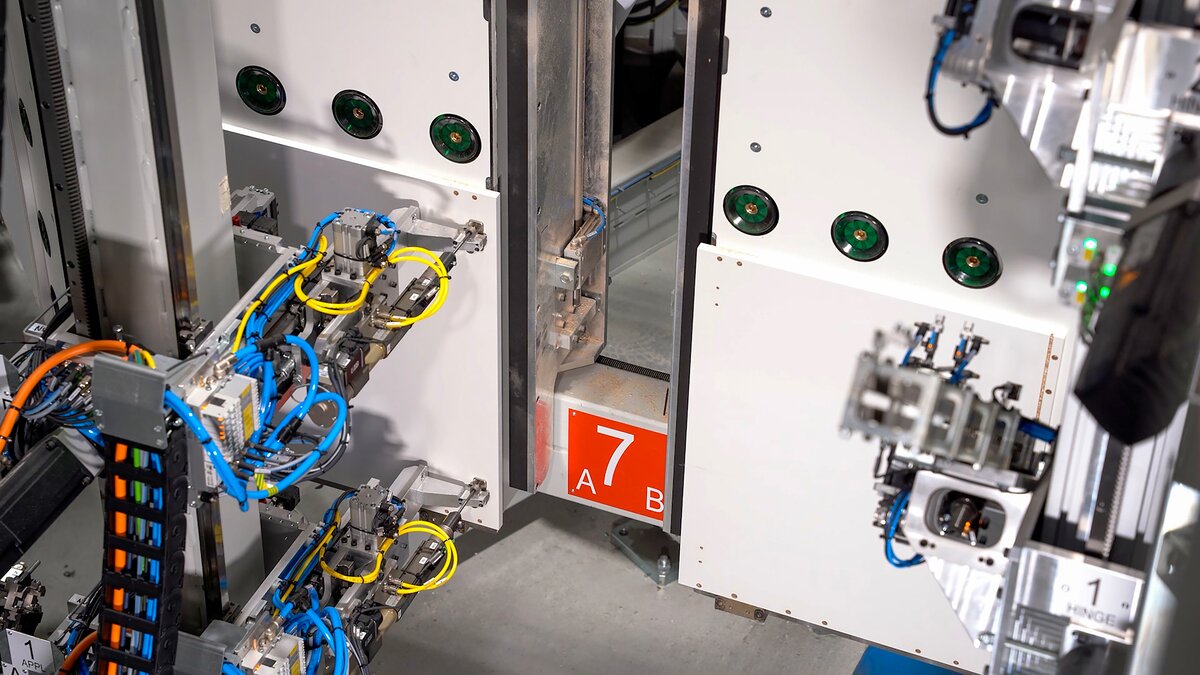

Automatic insertion of dowels and hardware for cabinet construction, including hinge bases, drawer rails, cabinet hangars, shelf supports, and front components such as hinges or drawer pulls. Our systems guarantee maximum precision and adaptability, with inserter groups designed to ensure maximum reliability, even in the most intensive production cycles.

Discover Tecno Logica’s solutions

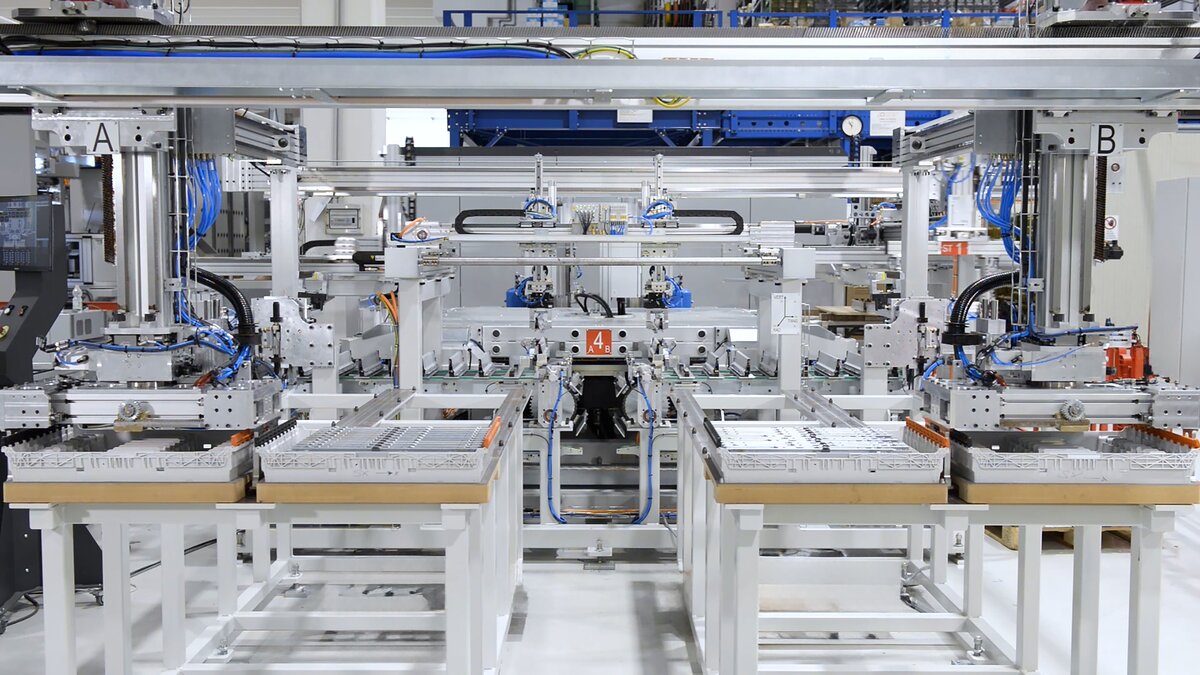

Assembly

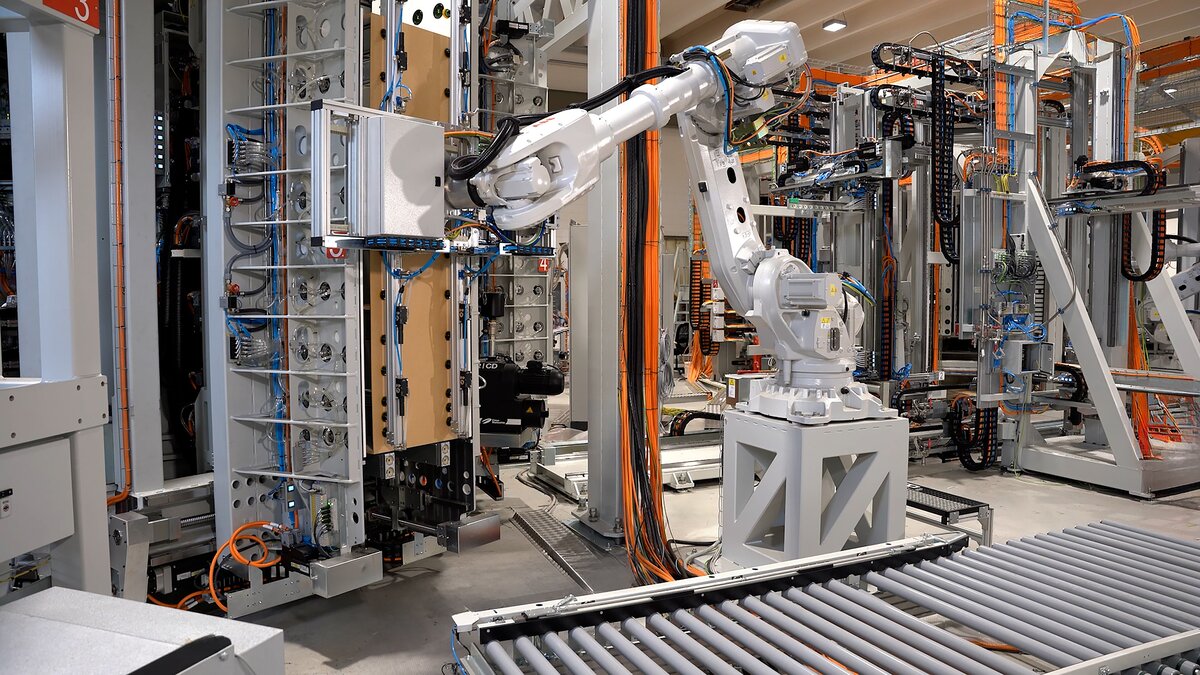

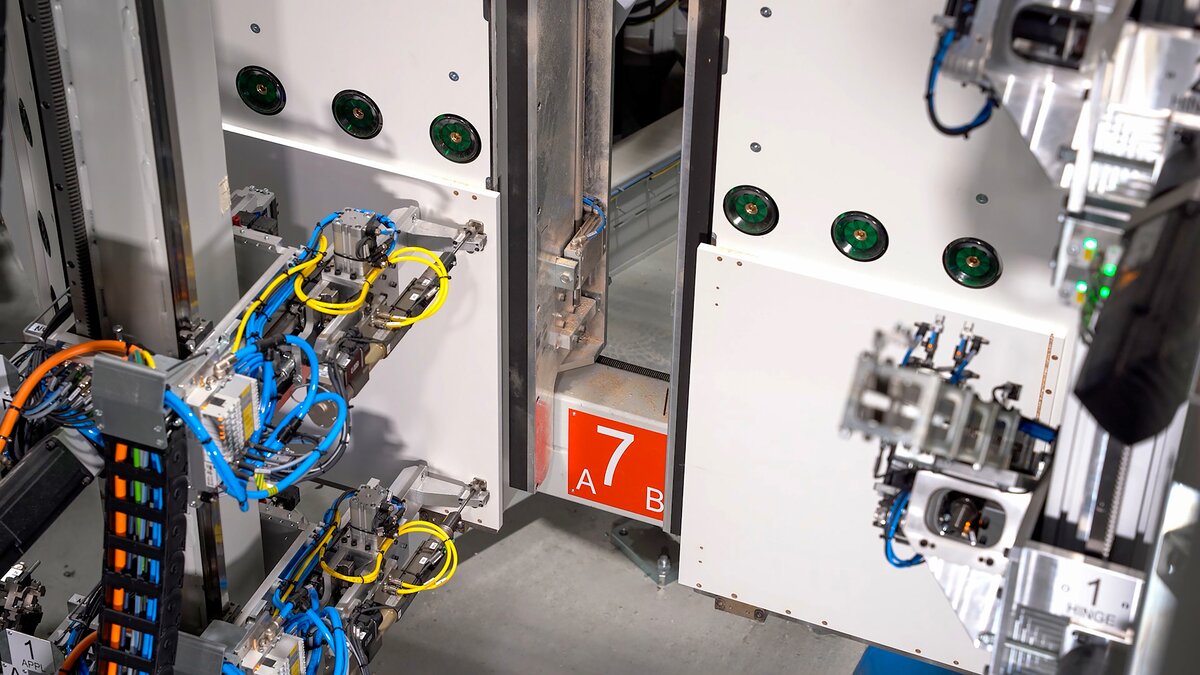

Automatic Drawer Insertion

In the automatic cabinet production process, no operation is excluded: even the insertion of the drawers is completely automated, thus completing the cabinet. An innovation that redefines production standards.

Automatic Door Insertion

In the automatic cabinet production process, no operation is excluded: even the assembly of the door on the assembled cabinet is completely automated, thus completing the product. An innovation that redefines production standards

Packaging

In the cabinet production flow, automation extends to the packaging phase, ensuring a fully integrated process. Automated order sorting allows efficient management of palletization and package accumulation, optimizing end-of-line logistics.

Discover Tecno Logica’s solutions

Tecno Logica stands out for its process expertise and cutting-edge levels of innovation, offering modular, scalable and innovative solutions for the factory of the future. In this context, we have worked to respond to a concrete market need: a complete and versatile solution for the automatic assembly of drawers, whether they are made of wood or metal, to be assembled by screwing or pressing, or made of wood with folding technology. The adaptability of our drawer assembly solutions allows us to meet different production requirements, with capacities ranging from 4 to 10 pieces per minute. Our systems can be configured to include or exclude, depending on requirements, additional processes such as machining and assembly of the front or other components, always ensuring optimal integration in a wide variety of production contexts. We manage the assembly of drawers from different suppliers, including of course the most common market players. We offer our expertise and experience for the design and implementation of infeed systems or material preparation systems, an integral part of the production process for which we normally take charge.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Drilling

High precision drilling with automatic systems, configurable for different applications and materials, ensuring speed, repeatability and quality of the process. Particular attention is paid to the dust extraction systems, ensuring maximum cleanliness of the workpiece and the surrounding environment.

Discover Tecno Logica’s solutions

Hardware Insertion

Automatic insertion of door hardware, including hinges, locks or handles and other accessories and components.

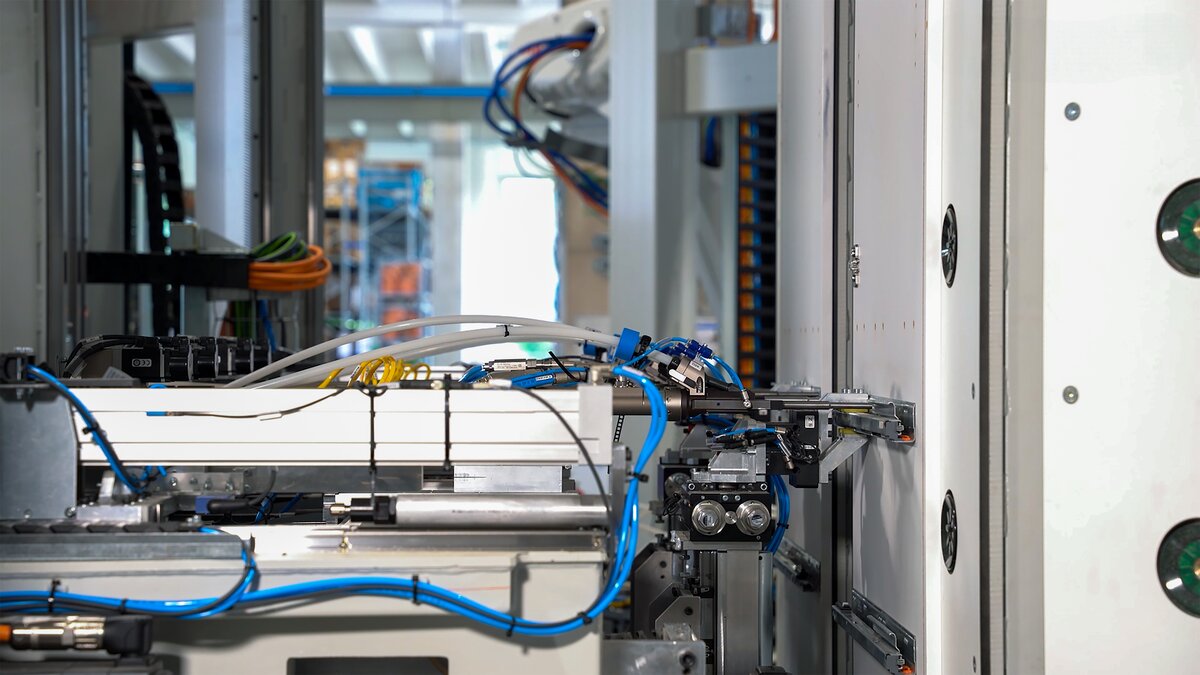

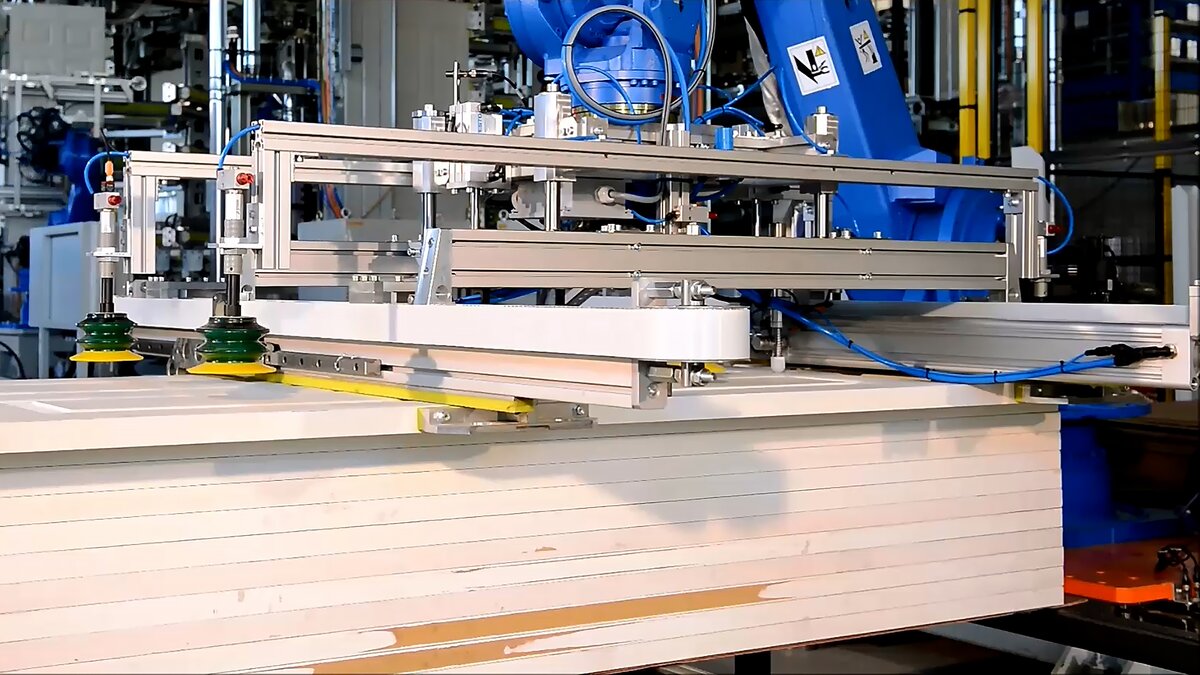

Assembly

Automatic cabinet assembly through the handling of all its components: side panels, horizontal elements, and back panel are positioned, pressed, and stapled when required. The process ensures a solid and precise joint.

Discover Tecno Logica’s solutions

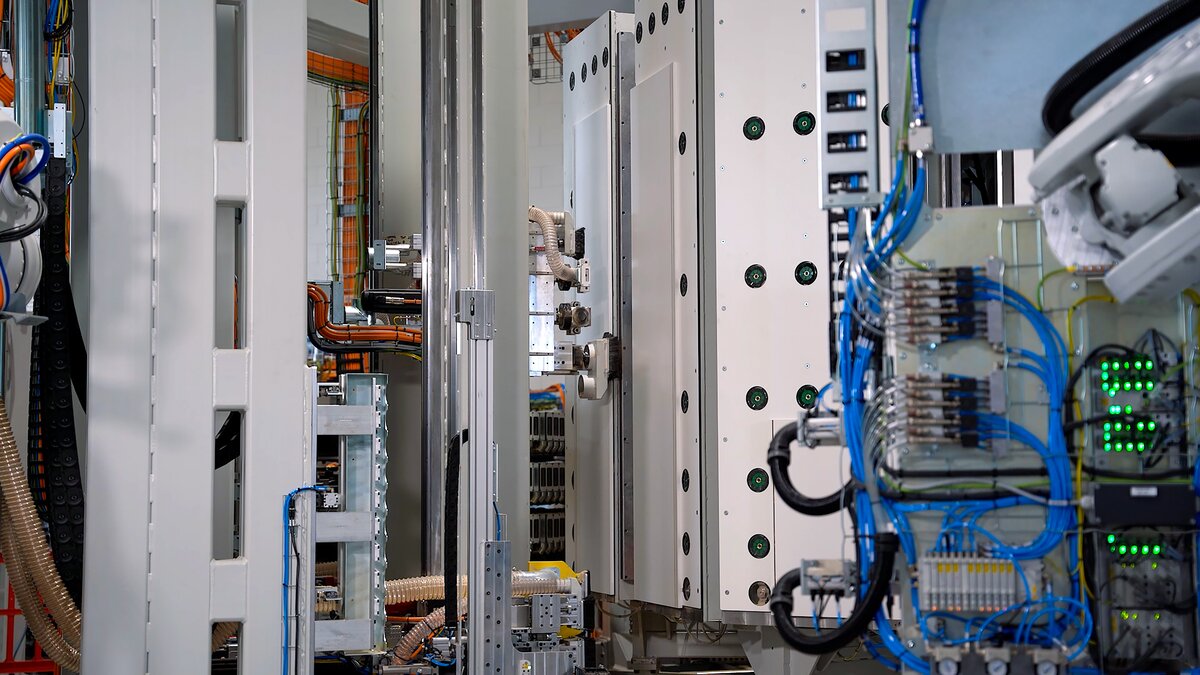

Tecno Logica develops cutting-edge systems designed to optimize the drilling, routing, and hardware insertion processes for cabinet doors, combining precision, performance, and efficiency.

Thanks to the modularity of our solutions, our systems can be easily integrated into a wide range of production environments, offering high versatility to meet specific requirements in terms of space, process configuration, production volumes, and batch sizes.

Our equipment is engineered to perform all operations automatically — from drilling and routing to the accurate placement of hinges and/or bumpers, whether screwed or press-fitted — ensuring consistent quality standards while reducing cycle times.

With our technologies, we aim to drive the woodworking industry toward higher levels of automation, enhancing production performance and the competitiveness of manufacturers operating in this sector.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Drilling

High precision drilling with automatic systems, configurable for different applications and materials, ensuring speed, repeatability and quality of the process. Particular attention is paid to the dust extraction systems, ensuring maximum cleanliness of the workpiece and the surrounding environment.

Milling

High precision milling with automatic systems configurable for different applications. We guarantee speed, repeatability and quality of the process, Integrating high-performance dust extraction solutions to keep both the workpiece and the surrounding environment clean.

Hardware Insertion

Automatic insertion of door hardware, including hinges, locks or handles and other accessories and components.

Discover Tecno Logica’s solutions

Tecno Logica manufactures solutions dedicated to the finishing of kitchen worktops, developed to meet the growing needs for automation and processing quality in the wood industry.

We offer complete lines that integrate advanced edgebanding and coating technologies, ensuring flawless finishes and optimal adhesion. In addition, with our handling systems, we ensure a taut and continuous production flow, eliminating downtime and optimizing the efficiency of the entire process.

Our solutions help companies in the industry reach new targets in automation, competitiveness and productivity, while maintaining a high quality standard.

Tecno Logica develops advanced systems for the complete production of door panels, meeting the need for high performance and adaptability to various production variables.

The production process covers all key phases: from cutting the raw material, expanding the honeycomb core, and subsequent gluing, to surface lamination and pressing, and finally the finishing of the completed product. Integrated automation technologies and efficient handling systems ensure operational continuity, precision, and speed, guaranteeing a smooth and optimized production flow.

With our systems, companies can achieve new levels of competitiveness, responding promptly to market demands without compromising on product quality or production efficiency.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

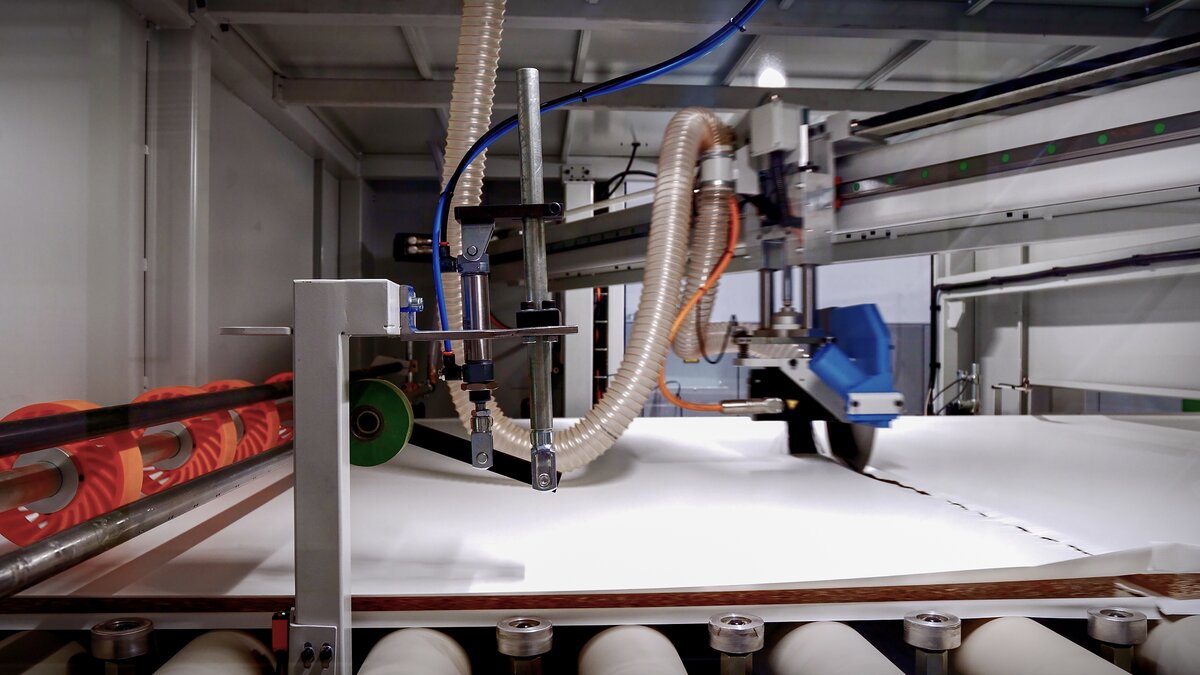

Door Panel Building

Automated door panel construction, with assembly of internal components and management of filling and covering materials with gluing and pressing. The process guarantees high precision, structural quality and maximum production efficiency.

Internal factory logistics

From the sorting of materials and components to the integration and connection between different production processes. Tecno Logica offers industrial solutions for an efficient and continuous flow.

Door Machining

Automated door processing through high-precision milling, performing all the necessary operations on the already assembled panel. The systems guarantee performance, repeatability and quality, with particular attention to the dust extraction systems, ensuring maximum cleanliness of the piece being processed and the surrounding environment.

Hardware Insertion

Automatic insertion of door hardware, including hinges, locks or handles and other accessories and components.

Discover Tecno Logica’s solutions

Tecno Logica develops advanced solutions for the production of doors, creating systems that respond both to the need for high performance by working in batches, and to the need for maximum flexibility with the management of batch 1, with the ability to adapt to different production variables. Our solutions cover all the main drilling and milling operations for interior and exterior doors, of different materials and finishes. By integrating advanced handling systems, we ensure a continuous and perfectly coordinated flow, minimising waiting times and improving the overall efficiency of the production line. With these solutions, companies can optimise their production process, increasing competitiveness and responsiveness to market demands for speed.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Door Machining

Automated door processing through high-precision milling, performing all the necessary operations on the already assembled panel. The systems guarantee performance, repeatability and quality, with particular attention to the dust extraction systems, ensuring maximum cleanliness of the piece being processed and the surrounding environment.

Hardware Insertion

Automatic insertion of door hardware, including hinges, locks or handles and other accessories and components.

Discover Tecno Logica’s solutions

Tecno Logica offers integrated solutions for the automated production of honeycomb panels, a key technology for the RTA furniture sector, door production and all other areas where the combination of lightness and strength is required. Our plants are designed to meet the demands of high-volume production, but also to ensure maximum flexibility within the production mix, depending on the customer's needs.

The honeycomb panel's production includes several crucial stages, such as the cutting and preparation of the materials, the assembly of the internal structure (if any), the insertion of the honeycomb and the subsequent closing of the panels with a surface finish. With our facilities, we manage each step of the process in an automated manner, optimising the efficiency and quality of the final product.

In addition, we offer a complete handling system that integrates all necessary operations, from material picking to the management of machine loading and unloading, ensuring a continuous and uninterrupted flow. Our solutions are perfect for those who need to handle large volumes, but also for those who need to respond to flexible production demands, with small production batches and a quick setup for product changeovers.

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Stile cutting

Precise cutting of materials for the construction of the honeycomb panel, ensuring waste optimization and maximum production efficiency. The process ensures high quality and uniformity of the components.

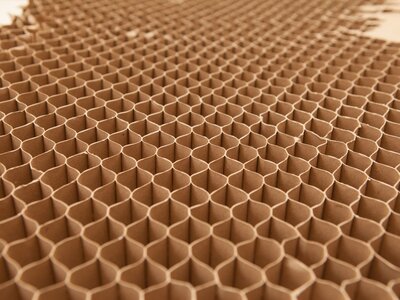

Honeycomb expansion and handling

Expansion, gluing and handling of the honeycomb for the construction of light panels. The process guarantees a uniform opening of the honeycomb structure and precise positioning, ensuring stability and lightness to the finished panel.

Top and cover insertion

Automatic insertion of top and cover into the honeycomb panel, with precise positioning and optimized gluing. The process guarantees structural solidity, flatness and quality of the finished product.

Sectioning

Precise cutting of the material to eliminate excess and perfectly finish all sides of the product.

Final Palletizing

Pallet creation with automatic or robotic systems. The finished product is stacked ready for the next destination.

Discover Tecno Logica’s solutions

Picking

Material and component picking and feeding systems adapted to the specific context using the most cutting-edge technologies

Stile cutting

Precise cutting of materials for the construction of the honeycomb panel, ensuring waste optimization and maximum production efficiency. The process ensures high quality and uniformity of the components.

Honeycomb expansion, gluing and handling

Expansion, gluing and handling of the honeycomb for the construction of light panels. The process guarantees a uniform opening of the honeycomb structure and precise positioning, ensuring stability and lightness to the finished panel.

Top and cover insertion

Automatic insertion of top and cover into the honeycomb panel, with precise positioning and optimized gluing. The process guarantees structural solidity, flatness and quality of the finished product.

Sectioning

Precise cutting of the material to eliminate excess and perfectly finish all sides of the product.

Final Palletizing

Pallet creation with automatic or robotic systems. The finished product is stacked ready for the next destination.

Discover Tecno Logica’s solutions

We are ready to listen, analyze and build tailor-made solutions for you.

Fill out the form below and one of our experts will contact you as soon as possible.