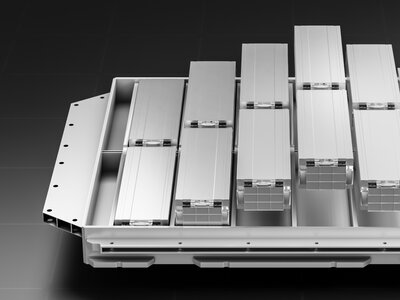

Tecno Logica develops systems for the processing of high-pressure die-cast components (HPDC), designed to guarantee maximum precision and operational continuity. From deburring to mechanical processing, up to quality controls, each phase is managed with advanced technologies to optimize productivity and guarantee reliable and repeatable results.

- Production performance: high-speed processing with multi-axis and multi-spindle support to reduce cycle times.

- Total integration: complete automation of handling, processing and control processes, with centralized management and real-time monitoring.

- Operational versatility: systems designed to adapt to different geometries and types of die-cast components, ensuring rapid format change.

We design custom systems tailored to every need.

Optimizing the production process is not merely a goal—it’s a competitive edge. Our systems enable a quick return on investment by enhancing productivity and cutting operational costs, effectively meeting the challenges of an ever-evolving market.

Tecno Logica stands out for its process expertise, offering modular, scalable and integrated solutions for the factory of the future. From extrusion bar to mechanical processing to assembly systems, the company is able to solve the most complex requirements and, as a system integrator, can take on the overall responsibility for turnkey systems.

In the dynamic and constantly evolving environment of the automotive sector, Tecno Logica integrates multi-axis rotary transfers and multi-spindle milling with robotic handling solutions, washing and welding systems. Our solutions minimize the resources involved in plant management and logistics costs by operating on all phases of the process. The main operations managed by Tecno Logica plant solutions include:

- Automation and handling

- Cutting

- Probing

- Milling

- Drilling

- Laser marking

- Deburring

- Chip removal

- Washing

- Riveting

- Fastener driving

- Welding

- Quality control

- Palletizing

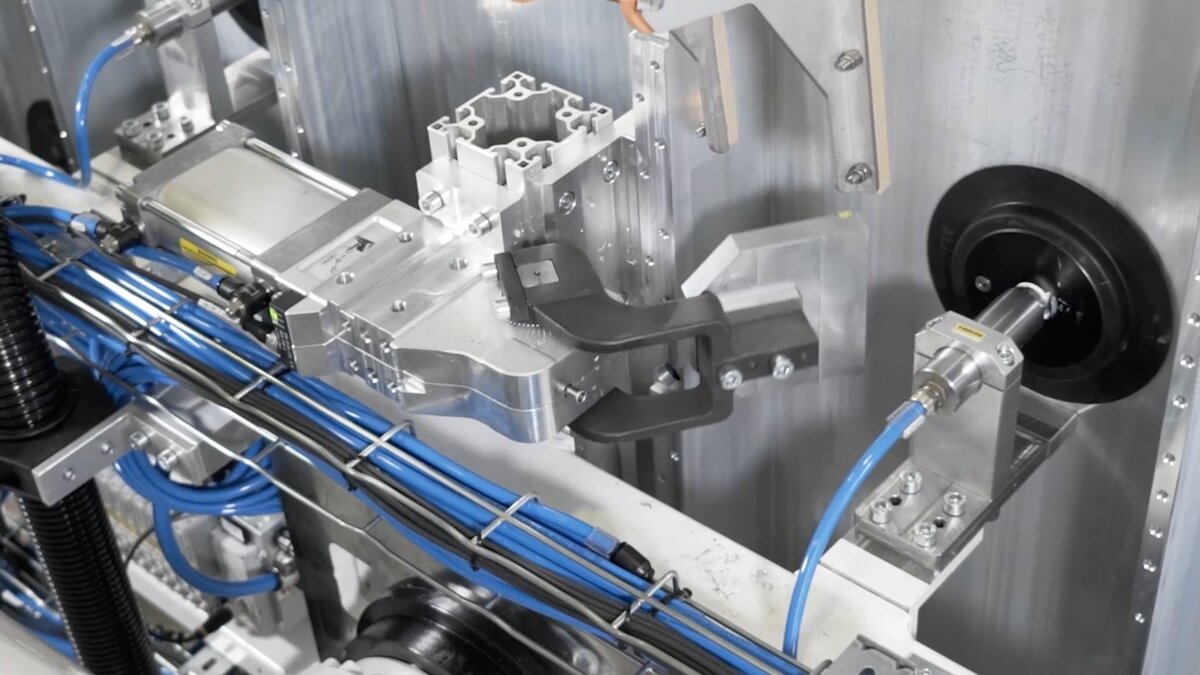

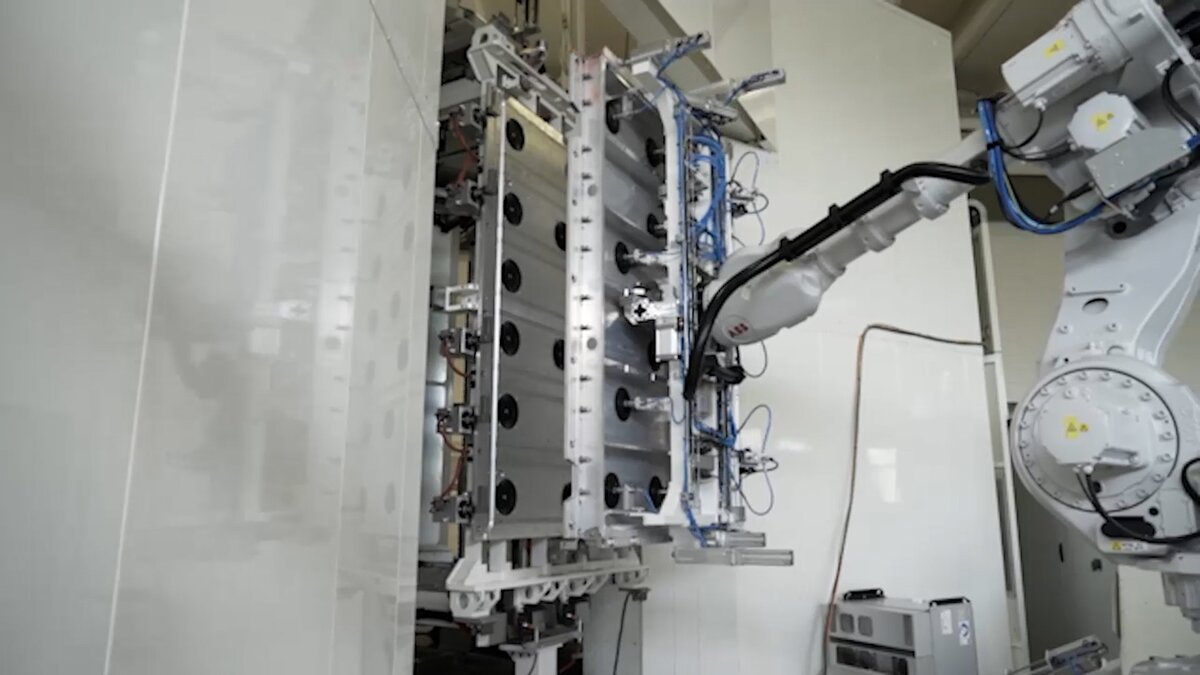

Automation & Handling

Automation and management of product flows through the use of advanced technologies to improve production efficiency, precision in handling and reducing the need for human intervention.

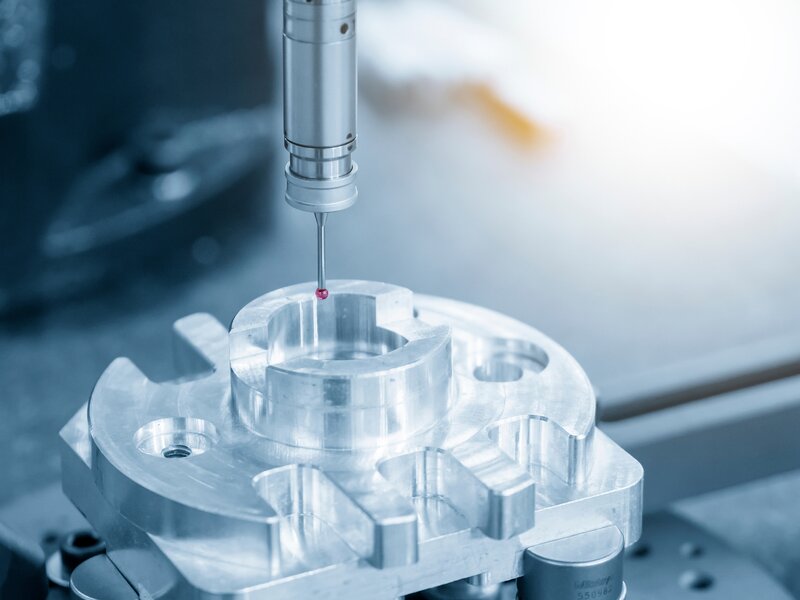

Probing

Part inspection and probing solutions automate part setup, in-cycle calibration, tool setting, and broken tool detection. Combined with automatic offset update systems, our technology reduces setup time and improves process control, so you can machine your parts with greater confidence.

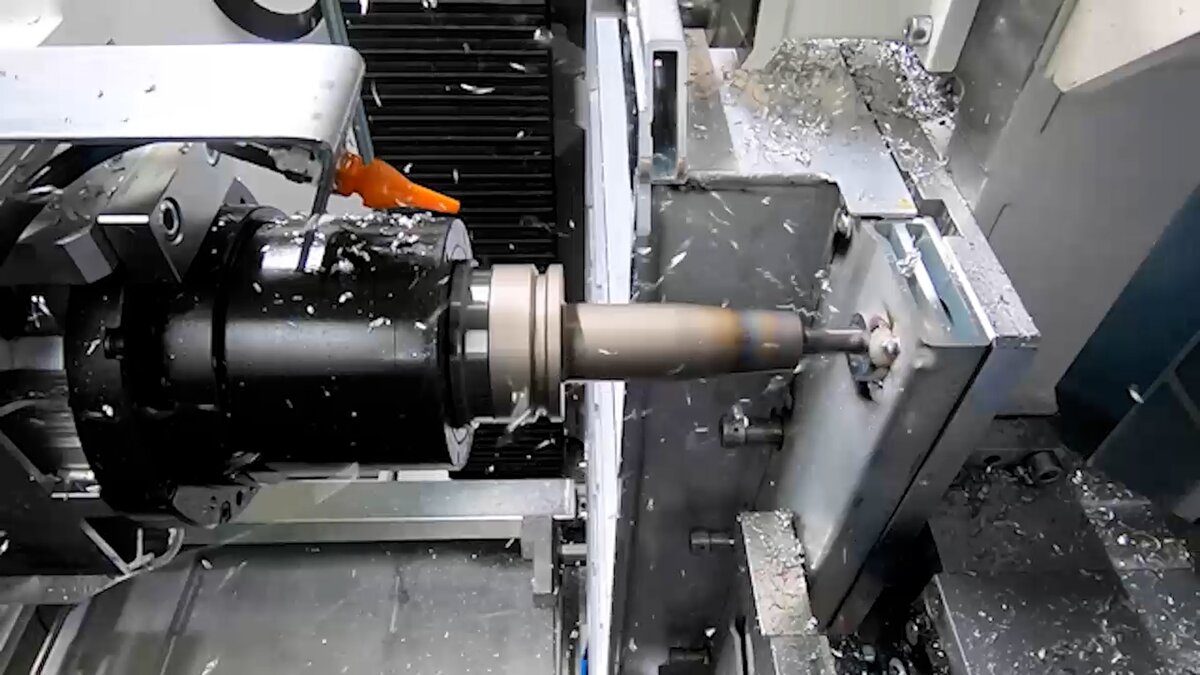

Milling

High precision milling with automatic systems configurable for different applications. We guarantee speed, repeatability and process quality, integrating high performance micro-lubrication solutions.

Discover Tecno Logica’s solutions

Discover more applications for the Automotive sector

We are ready to listen, analyze and build tailor-made solutions for you.

Fill out the form below and one of our experts will contact you as soon as possible.